Table Of Contents

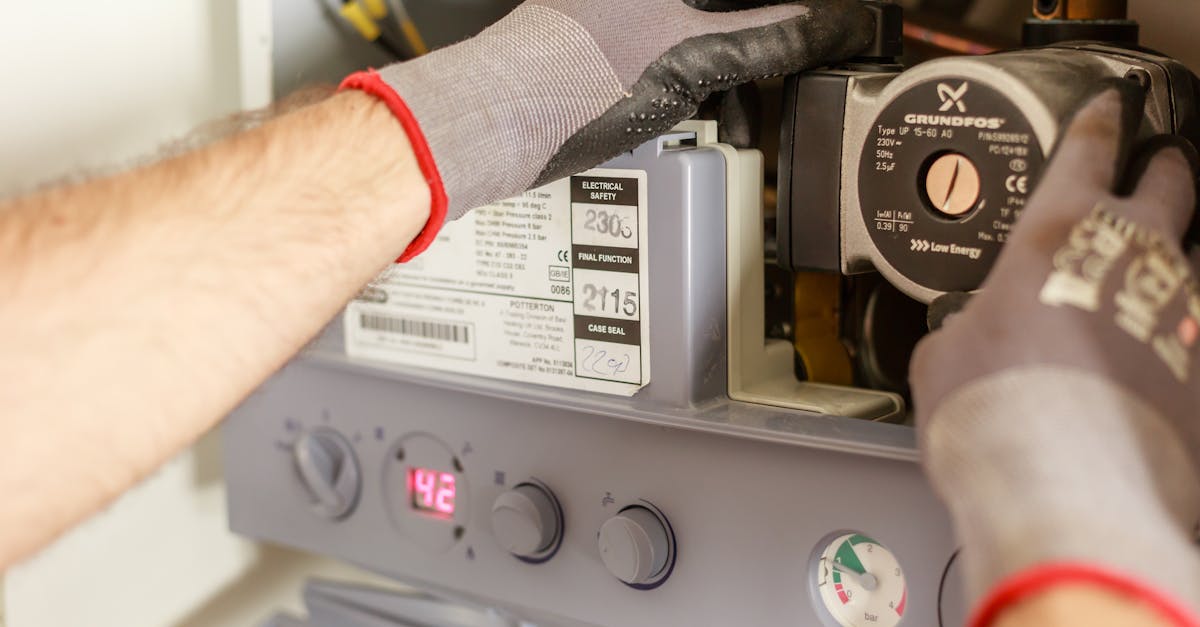

Role of Certifications in Gas Compliance

Certifications play a crucial role in ensuring compliance within the gas industry. They provide a framework for assessing the skills and knowledge required for safe practices in gas line installation and repair. By obtaining certification from recognised bodies, professionals demonstrate their competence and adherence to industry standards. This not only helps to maintain safety but also instils confidence among clients and stakeholders regarding the quality of the work being performed.

Furthermore, certifications often serve as a benchmark for ongoing training and education. Gas line installation and repair professionals must keep their skills up-to-date in a constantly evolving industry. Certification bodies typically require regular renewal processes, ensuring that workers are familiar with the latest technologies, regulations, and safety protocols. This commitment to continual learning enhances overall compliance and mitigates potential risks associated with gas operations.

Recognised Certification Bodies

Certification bodies play a crucial role in ensuring that professionals in the gas industry meet the required standards for safety and compliance. These organisations provide a framework for training and assessment that is recognised nationally. Recognised certification bodies focus on essential skills and competencies necessary for tasks such as gas line installation and repair. By achieving certification, workers demonstrate their commitment to safety and industry best practices.

Many of these bodies are accredited by government regulatory authorities. They offer various courses and training programs tailored to the needs of the gas sector. This includes not only initial training but also ongoing education to keep skills current. Being associated with a recognised certification body enhances a worker's credibility and ensures they are equipped to handle the challenges of gas line installation and repair effectively.

Continuous Professional Development in Gas Works

Continuous professional development (CPD) is crucial for professionals in the gas industry to maintain their skills and knowledge. This ongoing education ensures that workers remain competent in essential practices and safety standards. As technology evolves, training programs become necessary to cover new methods and equipment. Regular workshops, seminars, and online courses offer opportunities for workers to enhance their expertise. Knowledge gained through these avenues directly impacts the quality and safety of processes such as gas line installation and repair.

The gas industry faces constant changes in regulations and safety standards. Professionals must engage in CPD to stay informed about these developments. Being updated on industry trends contributes to better job performance and ensures compliance with the latest legal requirements. By prioritising continuous learning, workers not only improve their individual capabilities but also help foster a culture of safety and responsibility within their organisations. Investing time in professional development ultimately leads to more effective gas line installation and repair practices throughout the industry.

Staying Updated with Industry Changes

The gas industry is subject to a variety of regulations and standards that can change frequently. Staying informed about these changes is essential for professionals involved in gas line installation and repair. Regular engagement with industry publications and updates from regulatory bodies can provide insights into new legal requirements and safety standards. Further, participating in workshops and seminars can enhance a worker's understanding of best practices and emerging technologies.

Networking with peers in the field also plays a crucial role in staying current. By joining professional associations, gas workers can access resources and share knowledge regarding the latest developments in gas line installation and repair. Establishing connections with experienced professionals can facilitate mentorship opportunities and provide guidance on navigating complex regulatory environments. Continuous engagement with both informal and formal sources of information is vital to maintaining compliance and ensuring safety in gas operations.

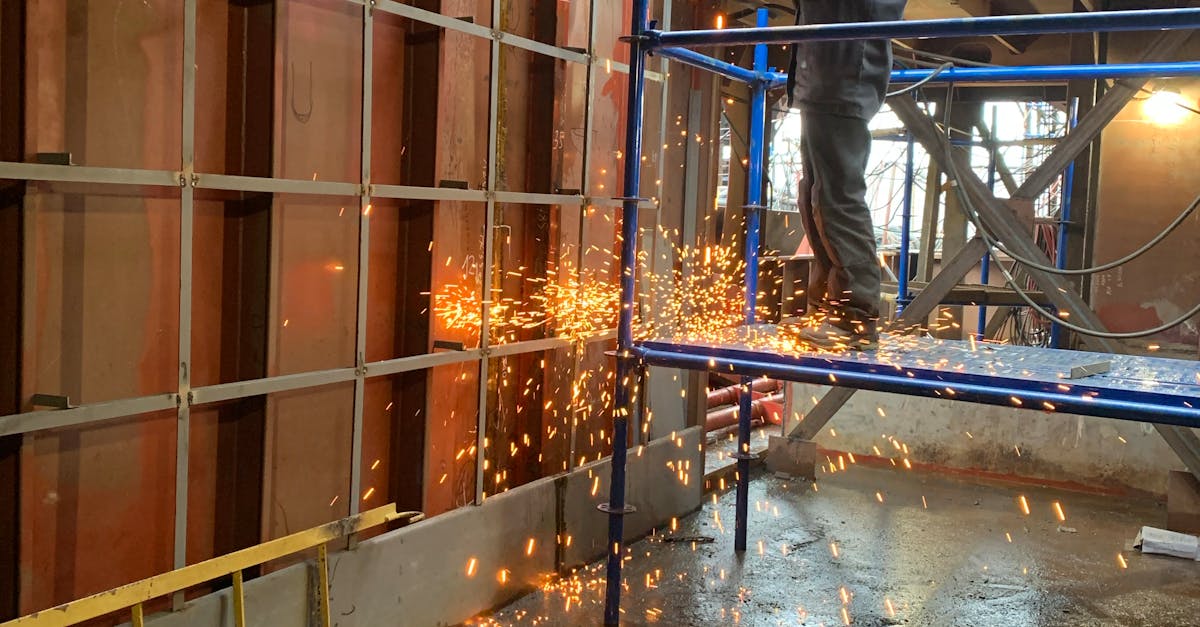

Impact of NonCompliance in Gas Operations

Non-compliance in gas operations can result in severe consequences for both workers and employers. Safety risks significantly increase when regulations are overlooked, leading to potential hazards such as gas leaks, explosions, or fires. The repercussions extend beyond immediate safety concerns, including potential legal ramifications and liabilities for companies failing to adhere to industry standards. For workers, the exposure to unsafe working conditions can lead to injuries or health issues, ultimately jeopardising their careers and well-being.

The impacts of non-compliance also resonate in financial terms. Companies may face hefty fines, increased insurance premiums, and the cost of rectifying unsafe installations. Gas line installation and repair, crucial to maintaining infrastructure integrity, can be severely compromised by negligence. Additionally, reputational damage can occur, leading to loss of client trust and, consequently, business opportunities. Balancing compliance with effective operational practices is essential for sustainable success in the gas industry.

Consequences for Workers and Employers

Non-compliance with gas safety regulations can have severe repercussions for both workers and employers. For individuals involved in gas line installation and repair, failure to adhere to proper procedures increases the risk of accidents and exposes them to potential legal action. Workers may face disciplinary measures, including suspension or termination, and could be liable for damages resulting from unsafe practices. The emotional toll of working in unsafe conditions can also affect employee morale and mental well-being.

For employers, the implications of non-compliance extend beyond immediate penalties. Fines and legal liabilities can accumulate quickly, straining financial resources and damaging the company’s reputation. Regulators may impose stricter oversight, leading to increased operational costs. Employers must prioritise safety training in gas line installation and repair to safeguard their workforce and maintain compliance. A culture of accountability and adherence to standards is essential for their ongoing success.

FAQS

Why is certification important in gas compliance?

Certification ensures that gas workers have met specific industry standards and possess the necessary skills and knowledge to carry out their responsibilities safely and effectively.

What are some recognised certification bodies for gas compliance in Australia?

Recognised certification bodies include the Australian Gas Association (AGA), the Plumbing Industry Commission (PIC), and the National Association of Testing Authorities (NATA).

How can gas workers ensure they stay updated with industry changes?

Gas workers can stay updated by participating in continuous professional development (CPD) courses, attending industry seminars, and subscribing to relevant industry publications and updates.

What are the potential consequences of non-compliance in gas operations?

Consequences of non-compliance can include legal penalties, fines, increased insurance costs, and most importantly, risks to safety that could lead to accidents or injuries.

What impact does non-compliance have on employers in the gas industry?

Non-compliance can result in significant financial losses for employers, including fines and litigation costs, damage to reputation, and potential loss of business due to safety violations.