Table Of Contents

Maintenance Requirements

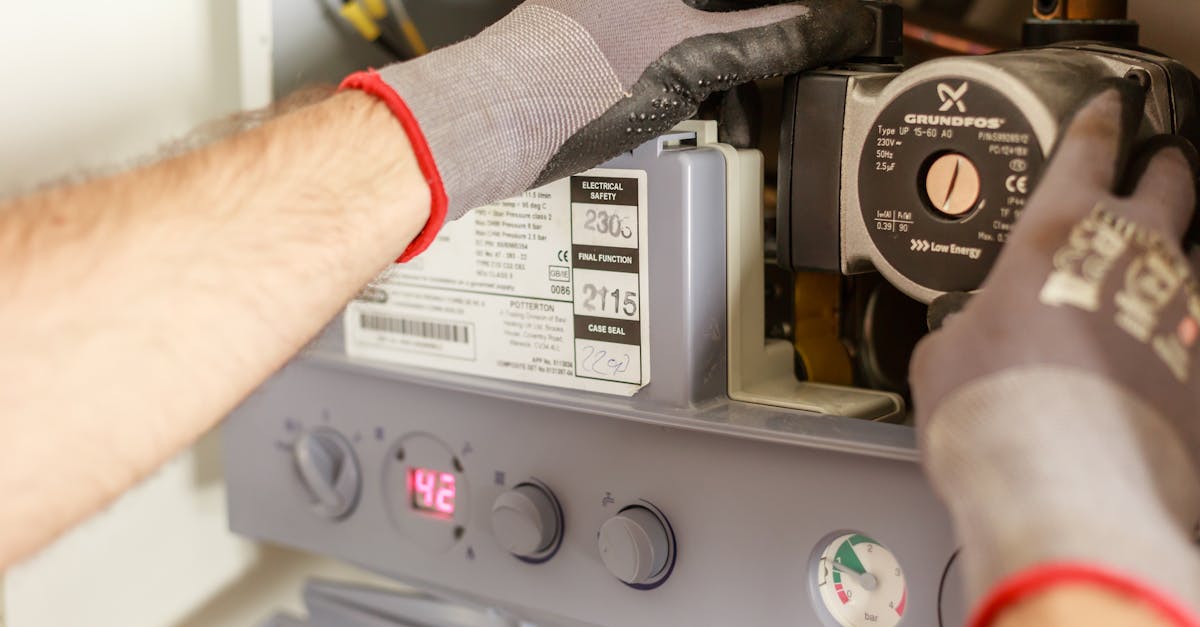

Regular maintenance of gas installations is crucial to ensure safety and efficiency. This involves conducting periodic inspections and testing of all components, including gas lines and appliances. Identifying potential leaks, corrosion, or malfunctions early can prevent serious hazards. Adhering to the AS/NZS 5601 standard significantly aids in establishing a comprehensive maintenance schedule that highlights the necessary checks at defined intervals.

Gas line installation and repair must be carried out by qualified professionals who understand the specific requirements set out in the standard. Routine maintenance not only involves technical inspections but also requires documentation of service history to track any issues over time. Maintaining accurate records helps in compliance with regulatory obligations and enhances the overall safety of gas systems in residential and commercial settings.

Regular Checks and Inspections

Routine inspections are essential for ensuring the safety and efficiency of gas installations. Regular checks should be conducted to identify potential leaks or faults. This practice not only protects the integrity of the gas line but also helps prevent accidents that could arise from undetected issues. Maintaining a schedule for these inspections allows for early detection of problems, thereby reducing the risk of hazardous situations.

Professionals engaged in gas line installation and repair must adhere strictly to the AS/NZS 5601 standard during inspections. This includes verifying that all components are functioning correctly and that the installation complies with regulatory requirements. By performing thorough checks, professionals ensure that gas appliances operate safely and efficiently, thereby safeguarding both property and the people who use them.

Training and Qualifications for Installers

Proper training and qualifications for gas installers are essential to ensure safety and compliance with AS/NZS 5601. This standard specifies the necessary skills and knowledge required for professionals handling gas line installation and repair. Installers must complete accredited training programs that cover the technical aspects of gas systems, safety protocols, and local regulations. By possessing the right qualifications, installers can minimise risks associated with gas handling and protect both themselves and the public.

Certification plays a crucial role in maintaining industry standards for gas installations. Installers should obtain relevant licenses that demonstrate their capability to perform gas line installation and repair safely. Continuous professional development is also important, as it helps installers stay informed about new technologies and practices within the gas industry. Engaging in regular training keeps installers competitive and ensures they remain compliant with evolving safety protocols and legislative requirements.

Necessary Skills and Certifications

Proper skills and certifications are crucial for professionals engaged in gas line installation and repair. Installers must demonstrate a comprehensive understanding of relevant regulations, safety protocols, and technical standards to ensure compliance with AS/NZS 5601. This includes knowledge of gas systems, installation practices, and the correct use of tools. Certified training programs offer theoretical and practical components, equipping technicians with the necessary expertise to perform their roles safely and effectively.

Obtaining certification often involves passing exams that assess one’s knowledge of gas regulations and technical skills specific to gas line installation and repair. Continuing education is also essential, as it allows installers to stay informed about the latest advancements in technology and safety practices. Moreover, regular upskilling through workshops or training sessions enhances their ability to respond to evolving industry standards and best practices.

Updates and Amendments to the Standard

The AS/NZS 5601 standard is regularly updated to reflect advancements in technology and changes in safety practices. These amendments often address the growing complexity of gas systems and aim to enhance the safety and efficiency of gas line installation and repair. Industry professionals need to be aware of these updates to ensure compliance and to maintain high safety standards in their work.

Staying current with regulatory changes is crucial for all installers. Regular training sessions and workshops are encouraged to ensure that technicians are familiar with the latest revisions. Knowledge of updates not only facilitates better compliance but also helps in minimising risks associated with gas line installation and repair. This ongoing education supports the overall goal of improving safety across the industry.

Staying Current with Regulatory Changes

Staying current with regulatory changes is crucial for anyone involved in gas line installation and repair. The AS/NZS 5601 standard is subject to periodic updates that reflect advancements in technology, safety protocols, and industry best practices. Installers must regularly consult the relevant authorities and industry bodies to ensure compliance with the latest regulations. Keeping up to date not only enhances safety but also ensures the integrity of installations and repairs.

In addition to monitoring changes in the AS/NZS 5601 standard, ongoing professional development plays a key role in maintaining high standards in the field. Workshops, seminars, and online courses provide valuable insights into new techniques and regulatory requirements. Gas line installation and repair professionals should actively engage in these educational opportunities to refine their skills and knowledge. This commitment to continuous improvement is essential for delivering safe and reliable service to clients.

FAQS

What is AS/NZS 5601?

AS/NZS 5601 is an Australian and New Zealand standard that outlines the requirements for the installation of gas systems in buildings, ensuring safety and compliance with relevant regulations.

What are the maintenance requirements for gas installations under AS/NZS 5601?

The standard specifies regular checks and inspections to ensure gas installations are safe and functioning correctly. This includes visual checks, pressure testing, and servicing by qualified professionals.

What qualifications do gas installers need according to AS/NZS 5601?

Gas installers must hold the necessary skills and certifications as mandated by local regulations, including relevant training in gas installation and safety practices.

How often should gas installations be inspected?

The frequency of inspections can vary based on local regulations and the type of gas installation, but regular checks should be carried out at least annually or as specified in the maintenance requirements of AS/NZS 5601.

How do I stay updated on changes to AS/NZS 5601?

To stay current with updates and amendments to AS/NZS 5601, it is recommended to regularly check the official standards website, subscribe to industry publications, or participate in professional training sessions.