Table Of Contents

Gas Pipe Installation Guidelines

Proper gas pipe installation is crucial for safety and efficiency. All installations must adhere to the specific guidelines outlined in the relevant Australian standards. Attention to detail is essential when determining the correct size and type of gas pipe for the application. Pipe materials should meet industry specifications to ensure durability and resistance to corrosion.

Gas line installation and repair must be conducted by licensed professionals with the appropriate expertise. The installation process should include thorough assessments of the site, ensuring that pipes are laid with the correct gradient and secured firmly. Regular checks during and after installation help prevent potential leaks or hazards, contributing to overall system reliability.

Standards for Sizing and Material Selection

Selecting the appropriate size and material for gas pipes is crucial for ensuring efficiency and safety in gas appliances. The sizing is determined by factors including the total gas load of connected appliances and the distance the gas must travel. Oversizing can lead to pressure drops, while undersizing may result in inadequate gas supply. Utility companies often provide specifications that include tables and charts to assist professionals in determining the correct pipe diameter required for a safe installation.

Material selection is equally important, with choices typically including copper, polyethylene, and rigid steel. Each material has specific applications and advantages, such as resistance to corrosion or ease of installation. Compliance with the relevant Australian Standards is mandatory to guarantee that installations meet safety regulations. Gas line installation and repair must follow these guidelines to avoid potential hazards, ensuring that all components function efficiently and safely within the system.

Connection and Disconnection Procedures

Proper connection and disconnection of gas appliances is fundamental for ensuring safety and compliance with regulations. Before connecting a new appliance, it is crucial to inspect all fittings and connections. Any damage or wear in the components can lead to leaks, posing significant risks. Use appropriate tools designed for gas connections to avoid damaging the fittings. Ensure that the appliance is properly positioned and that all gas lines are securely tightened to prevent any potential mishaps.

When disconnecting appliances, take care to follow the prescribed procedures meticulously. Begin by shutting off the gas supply to the appliance to eliminate the risk of accidental release. It is advisable to document the disconnection process, noting the condition of gas lines for future reference. Gas line installation and repair should only be conducted by qualified professionals to guarantee adherence to safety standards. Regular training and awareness of guidelines for connection and disconnection can greatly reduce the risk of incidents.

Safe Practices for Handling Gas Appliances

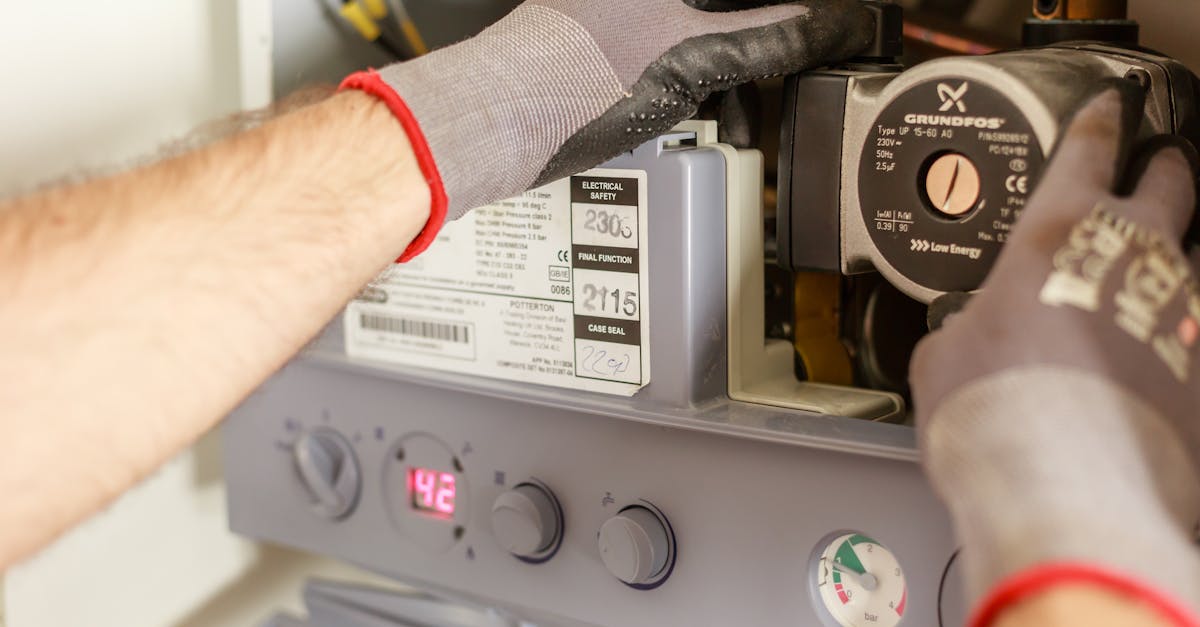

When handling gas appliances, it is imperative to prioritise safety and adhere to industry practices. Always ensure that the appliance is disconnected from the power supply before any handling. Proper personal protective equipment, such as gloves and goggles, should be worn to mitigate risks associated with gas exposure. Familiarity with the manufacturer’s instructions is crucial, as these guidelines will dictate safe handling procedures and any specific precautions needed for the particular appliance.

Gas line installation and repair requires a high level of skill and knowledge. Utilising trained professionals for such tasks is essential to prevent accidents or leaks. Before beginning any maintenance, check for visible signs of wear or damage on hoses and connections. Regularly training personnel on emergency procedures and the correct handling of gas appliances can further enhance safety. Ensuring that appropriate tools are readily available can simplify the process and reduce the chances of mishandling during repairs.

Maintenance and Inspection Protocols

Regular maintenance and inspection of gas appliances are essential to ensure safety and compliance with the relevant standards. Adhering to a set schedule allows for the early detection of potential issues that could pose hazards. Routine checks should cover critical components such as gas lines, connectors, and appliances themselves. Any signs of wear, corrosion, or leaks must be addressed promptly to maintain operational safety.

Gas line installation and repair should only be performed by qualified professionals to guarantee adherence to safety regulations. Periodic inspections should include testing for gas leaks, verifying the integrity of connections, and ensuring appliances operate efficiently. Documenting these inspections creates a reliable record for future reference and ensures accountability in maintaining high safety standards.

Routine Checks for Ensuring Safety and Compliance

Routine checks are essential to maintain the safety and compliance of gas appliances. Regular inspections help identify potential issues such as leaks, corrosion, or improper connections. Certified technicians should perform these checks to ensure all components meet regulatory standards. This not only safeguards users but also contributes to the longevity of the appliances and the overall efficiency of the gas system.

Gas line installation and repair play a crucial role in the integrity of the entire system. Visual inspections, pressure tests, and functional checks ensure that emergencies are prevented. Following a structured maintenance schedule helps in addressing minor issues before they escalate into larger problems. Compliance with established guidelines further assures the safe operation of gas appliances in residential and commercial settings.

FAQS

What are the key guidelines for installing gas pipes in New South Wales?

The key guidelines include following the relevant Australian Standards, ensuring correct sizing and material selection, and adhering to local regulations to promote safety and efficiency.

What standards should be followed for sizing and selecting materials for gas installations?

The Australian Standards, particularly AS/NZS 5601, provide specifications for the sizing and material selection of gas pipes, ensuring that they are appropriate for the type and volume of gas being used.

What are the procedures for safely connecting and disconnecting gas appliances?

Safe procedures involve ensuring the gas supply is turned off, using appropriate tools, wearing personal protective equipment, and consulting the manufacturer’s guidelines for specific connection and disconnection instructions.

What safe practices should be followed when handling gas appliances?

Safe practices include ensuring proper ventilation, checking for gas leaks, using equipment properly according to the manufacturer's guidelines, and avoiding any actions that could lead to accidents or gas exposure.

How often should gas appliances be inspected and maintained?

Gas appliances should be inspected and maintained regularly, ideally annually, to ensure they are functioning safely and efficiently. Routine checks should include looking for leaks, ensuring proper ventilation, and cleaning any components as needed.