Table Of Contents

Tightening Techniques for Leaky Joints

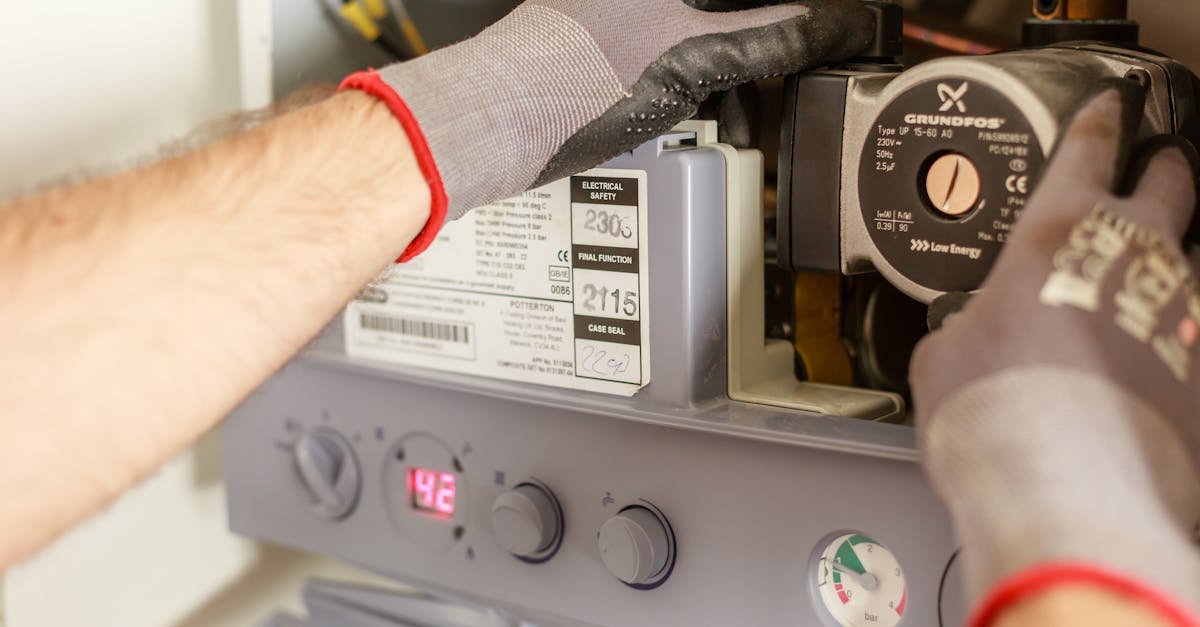

When addressing a leaky threaded joint, proper tightening techniques are essential. Begin by identifying the type of joint and the materials involved. Using the appropriate tools, apply a steady, even pressure to the joint. Start from the midpoint and work outwards, ensuring that you avoid creating any additional strain on the surrounding pipes. This controlled approach helps to prevent further leaks and maintains the integrity of the joint.

While tightening, be cautious of over-tightening, which can cause damage and lead to more significant issues. It’s also valuable to consider the specific requirements of your project, especially in contexts like gas line installation and repair. Always adhere to the manufacturer's guidelines for torque specifications and use a torque wrench if necessary. Regularly inspecting and adjusting joints can prevent leaks from occurring and ensure the long-term functionality of your piping systems.

Best Practices for Avoiding OverTightening

When addressing threaded joints, it is essential to use appropriate techniques to avoid over-tightening, which can lead to damage and further leaks. Employing a torque wrench to apply the correct amount of pressure ensures that connections are secure without exceeding the manufacturer's specifications. This practice is particularly crucial in gas line installation and repair, where both safety and functionality are paramount.

Regular inspections of the joint condition can prevent unnecessary adjustments that may lead to over-tightening. Using thread sealants or Teflon tape correctly can also aid in creating a reliable seal without the need for excessive force. Keeping an eye on the tightness of joints during routine maintenance helps identify potential issues before they escalate into larger problems.

Testing for Leaks After Sealing

After sealing a threaded joint, it is essential to conduct thorough testing for leaks to ensure safety and efficiency. One effective method is to apply a soapy water solution to the joint. The presence of bubbles indicates the presence of a leak. For more reliable detection, consider using a gas leak detector. This electronic device can identify even the smallest gas concentrations and provides a quick assessment of the joint's integrity.

Gas line installation and repair require strict adherence to safety guidelines. After sealing, maintain vigilance by monitoring the area for any unusual smells or sounds associated with gas. Regular checks can prevent potential hazards. It is advisable to inspect the joint under varying pressures to confirm that the repair holds up under operational conditions. This proactive approach safeguards not only the infrastructure but also the health and safety of those in proximity.

Methods to Ensure a Proper Seal

Ensuring a proper seal in threaded joints can significantly reduce the likelihood of leaks. One effective method involves using a suitable sealant specifically designed for threads. Applying the sealant evenly around the threads before tightening can help fill any gaps and create a tighter fit. In the case of gas line installation and repair, it is crucial to choose a sealant that is compatible with gas to prevent any dangerous leaks.

Another important consideration is the use of thread tape or PTFE tape. This tape can be wrapped around the male threads prior to assembly, providing an additional layer of protection against leaks. It's essential to apply the tape evenly and to avoid over-wrapping, as this can disrupt the fit of the joint. For gas line installation and repair, ensuring that the tape is compliant with gas regulations adds an extra layer of safety and reliability.

Maintenance Tips for Threaded Joints

Maintaining threaded joints is essential to ensuring their longevity and preventing leaks. Regular inspections can help identify any signs of wear or corrosion. If the joint appears to be in good condition, applying a suitable pipe joint compound or thread seal tape can enhance its sealing properties. This is particularly important in applications involving gas line installation and repair, where even the slightest leakage can lead to dangerous situations.

Proper tightening techniques also play a significant role in the maintenance of threaded joints. It is crucial to adhere to the manufacturer’s guidelines regarding torque specifications to achieve the right balance between tightness and the risk of over-tightening. Engaging in routine maintenance checks and addressing minor issues early can save time and prevent costly repairs down the line. Keeping a maintenance log can help track any repairs or inspections conducted on gas line installation and repair, ensuring that safety remains a top priority.

Preventive Measures to Avoid Future Leaks

To minimise the risk of future leaks in threaded joints, proper installation practices play a crucial role. Use appropriate thread sealing materials during the assembly process. This includes Teflon tape or thread sealant specifically designed for the types of fluids being handled. Ensure that the threads are clean and free from debris before applying any sealing material. Following the manufacturer's guidelines for torque specifications can also help maintain a secure connection without the need for excessive pressure.

Regular inspection and maintenance of threaded joints is essential for early identification of potential issues. Scheduled checks can help spot wear and tear before they develop into leaks. While performing maintenance, be mindful of the surrounding conditions that could contribute to joint degradation. High temperatures, vibration, and chemical exposure all pose risks. For safety reasons, always consult professionals when dealing with installations involving gas lines. Proper knowledge and experience are vital in gas line installation and repair to avoid complications and ensure system integrity.

FAQS

What are the common causes of leaks in threaded joints?

Common causes include improper sealing, wear and tear on the threads, over-tightening, and damage to the joint materials.

Can I use tape to fix a leaking threaded joint?

Yes, using plumber's tape (Teflon tape) can help seal the threads and prevent leaks. Ensure it is applied evenly and properly.

How can I tell if my threaded joint is leaking?

You can check for leaks by looking for water stains, dampness around the joint, or by applying a soapy water solution and observing for bubbles.

Is it safe to keep using a leaky threaded joint?

It is not advisable to continue using a leaky joint, as it can lead to water damage, increased bills, and further deterioration of the joint.

What preventive measures can I take to avoid future leaks in threaded joints?

Regular maintenance, using proper sealing materials, avoiding over-tightening, and inspecting joints periodically can help prevent future leaks.