Table Of Contents

Documentation Required for Compliance

Proper documentation serves as the backbone of compliance in gas line installation and repair. Required documentation typically includes detailed engineering plans, risk assessments, and site safety reports. These documents not only guide the installation process but also provide vital information to regulatory bodies regarding adherence to safety standards and gas regulations. Inspections and audits frequently rely on this documentation to ensure that all phases of the project are properly executed.

Another important aspect is the maintenance of records throughout the lifecycle of the gas line installation and repair. This includes documenting all inspections, tests, and maintenance activities performed over time. Accurate record-keeping enables installers to track compliance with applicable codes and standards while facilitating timely updates as regulations evolve. Such thorough documentation is essential for demonstrating the installation's safety and integrity to both clients and authorities.

Necessary Permits and Records

For any gas line installation and repair project, obtaining the appropriate permits is crucial to ensure legal compliance and safety. Local regulations will often dictate the specific permits required, which may vary from one jurisdiction to another. Commonly, a building permit is necessary along with specific gas installation approvals. Each permit serves to validate that the installation meets safety standards and requirements set forth by regulatory bodies. Failing to secure the proper permissions can result in costly fines or the need to redo work already completed.

Keeping meticulous records during the installation process is equally important. Documenting each step helps maintain transparency and accountability, ensuring that all aspects of the project comply with local guidelines. These records should include details of permits obtained, inspections conducted, and compliance certifications. Proper documentation helps protect installers and property owners, providing evidence of adherence to safety and legal standards should any disputes arise after the work is completed.

Common Mistakes to Avoid

One common mistake in gas line installation and repair is the lack of thorough documentation. Failing to maintain accurate records can lead to serious compliance issues. Many installers overlook the importance of keeping track of permits, inspections, and maintenance logs. Without this documentation, it becomes difficult to verify that all procedures met regulatory standards. This oversight may result in costly fines or even the need to redo installations.

Another frequent pitfall involves insufficient training and awareness of compliance requirements. Installers may not be familiar with the latest regulations or best practices specific to gas line installation and repair. Ignoring the need for proper certification and ongoing education can lead to non-compliance errors. This misstep not only jeopardises safety but could also leave businesses liable for any incidents that occur due to improper installation practices.

Pitfalls in Compliance Checklists

Compliance checklists are crucial for ensuring the safety and efficiency of gas line installation and repair. However, many professionals underestimate the importance of these documents. Some installers may fail to regularly review or update their checklists, resulting in outdated procedures that do not reflect current regulations. This oversight can lead to serious issues during inspections, jeopardising both the safety of the installation and the reputation of the contractor.

Another common pitfall involves the inconsistent application of checklists. Inexperienced installers might overlook critical items, assuming their prior knowledge suffices. This tendency becomes evident when they skip essential steps that are specific to particular projects or environments. Such gaps in compliance can create significant risks, highlighting the need for a thorough understanding and strict adherence to established guidelines in gas line installation and repair.

Training and Certification for Installers

Training and certification for installers plays a crucial role in ensuring the safety and integrity of gas line installation and repair. Practitioners must undergo rigorous training programs that cover the fundamentals of gas systems, safety protocols, and current regulations. These training sessions often include both theoretical and practical components, enabling participants to gain hands-on experience with gas line installations and repairs.

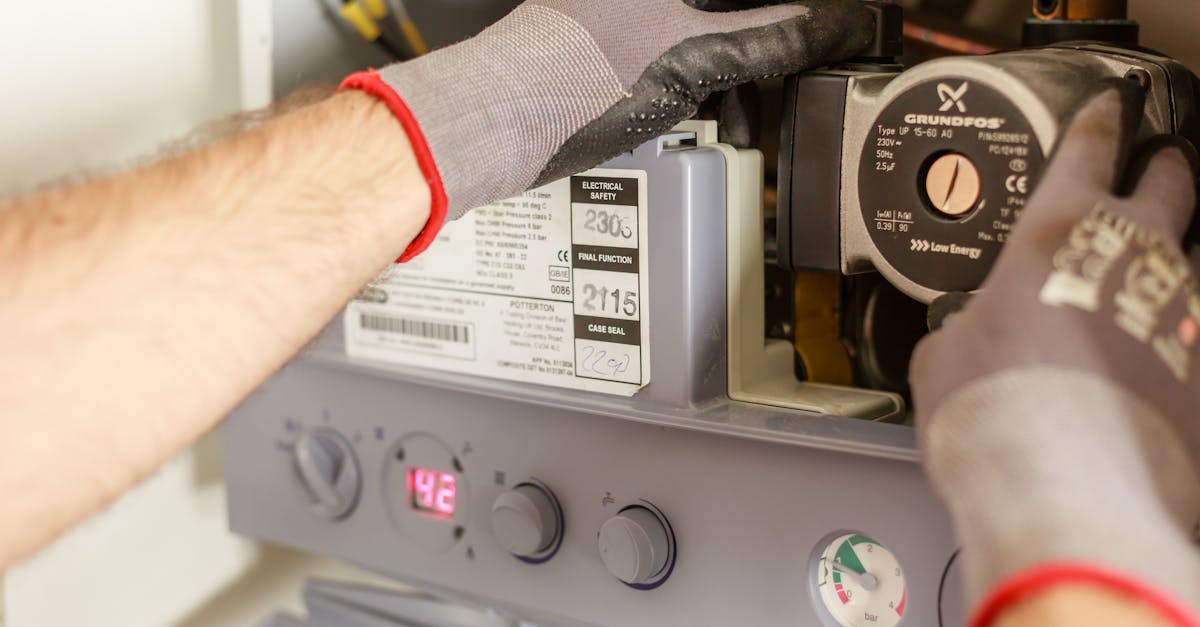

Certification programs are typically governed by standards set by local authorities and national organisations. Installers must demonstrate their proficiency in handling common tools, understanding gas flow dynamics, and conducting safety inspections. Proper certification not only guarantees adherence to compliance requirements but also reinforces the overall safety of gas line installation and repair operations.

Qualifications Needed for Compliance

Gas line installation and repair require specific qualifications to ensure safety and compliance with regulations. Installers need to hold a valid certification recognising their training and experience in handling gas systems. Recognised certifications can include those from industry bodies or state authorities. These qualifications not only provide assurance to clients but also indicate that the installer understands essential safety protocols and regulatory requirements.

It is essential for gas line professionals to undergo specialised training that covers installation techniques, safety measures, and relevant legislation. Continuous professional development is highly recommended, as it ensures installers remain updated with the latest practices and compliance standards. Understanding the complexities of gas line systems is crucial for maintaining safety and preventing hazardous situations during installation and repair work.

FAQS

What documentation is required for gas line installation compliance?

Documentation required typically includes installation plans, permits, inspection records, and safety compliance certificates. It's important to ensure all documents are up to date and readily available for review.

What are the necessary permits for gas line installations?

Necessary permits vary by state or territory but generally include building permits, gas installation permits, and any local council approvals. Always check with your local regulatory authority for specific requirements.

What are common mistakes to avoid during gas line installation?

Common mistakes include failing to obtain the necessary permits, not performing adequate safety checks, overlooking local codes and regulations, and using incorrect materials for installations.

What pitfalls should be noted in compliance checklists for gas line installations?

Pitfalls include incomplete checklists, not regularly updating compliance documents, and neglecting ongoing maintenance records. It's crucial to review and revise checklists to ensure they remain comprehensive and accurate.

What qualifications are needed for gas line installers to ensure compliance?

Installers typically need to hold relevant licenses, complete specific training programs, and possess certifications that demonstrate their understanding of safety standards and compliance regulations related to gas installations.