Table Of Contents

Choosing Qualified Professionals

When it comes to gas line installation and repair, selecting qualified professionals is essential to ensure safety and compliance with local regulations. Technicians should possess appropriate certifications and a solid track record in the industry. An understanding of the different types of gas systems and relevant safety standards is fundamental for anyone handling gas lines. It is advisable to look for professionals who are licensed and insured, providing assurance that they are qualified to perform necessary work.

Thorough vetting of potential technicians can include checking references and reviewing customer feedback. Reputable professionals often belong to industry associations, which can indicate a commitment to ongoing training and adherence to best practices. Asking about their experience with specific types of gas lines can also help in assessing their qualifications. Ensuring that technicians are knowledgeable about compliance regulations will contribute to the safety and longevity of any gas line installation and repair project.

Criteria for Selecting Certified Technicians

When selecting certified technicians for gas line installation and repair, it is essential to check their qualifications and licensing. Licensed professionals must adhere to stringent safety standards and regulations. Look for technicians who have completed relevant training programs and possess up-to-date certificates relevant to gas work. They should also have experience specifically related to gas systems, ensuring they are familiar with the complexities involved in installation and maintenance.

Assessing a technician’s reputation can also provide insights into their reliability and skill level. Reviews and testimonials from previous clients can highlight the quality of their work and their adherence to safety practices. Ensuring that the technician is insured is vital, as it demonstrates their commitment to safety and accountability. These criteria help guarantee that the professionals chosen for gas line installation and repair are equipped to handle the task safely and effectively.

Common Tools for Gas Line Maintenance

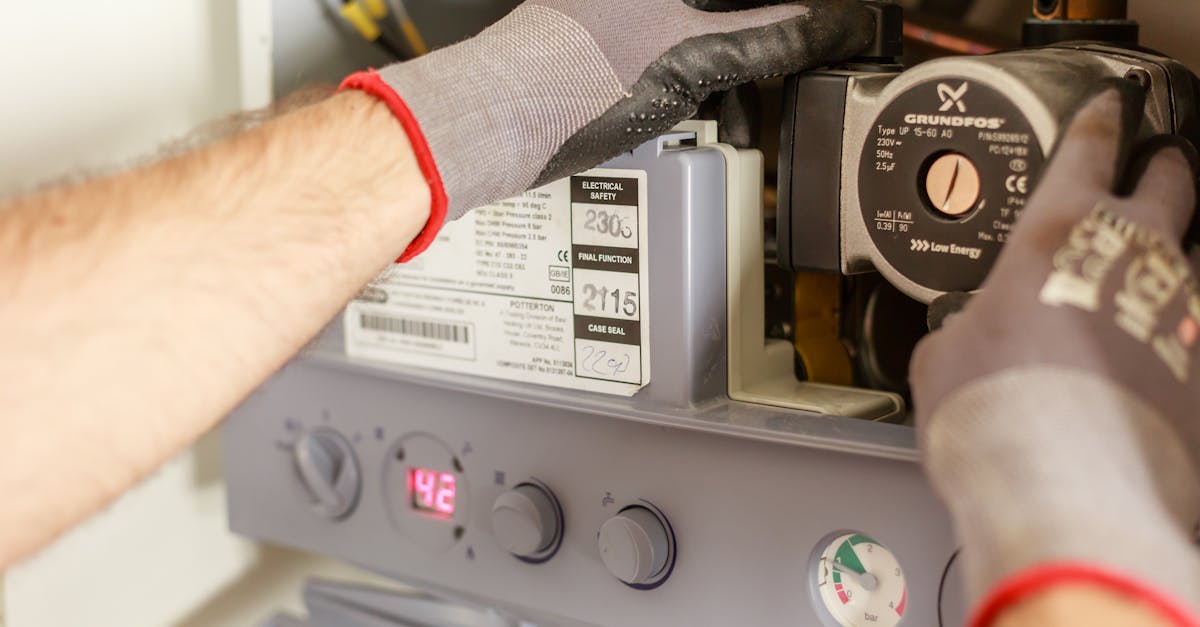

Effective gas line maintenance relies on a range of specialised tools that ensure safety and efficiency during gas line installation and repair. Wrenches, specifically pipe wrenches, are essential for securely tightening and loosening fittings. Gas leak detectors are also vital for identifying any potential leaks quickly. Additionally, pressure gauges allow technicians to monitor gas pressure levels, ensuring they remain within safe operating parameters.

Another important tool is the tapping machine, used for safely connecting to live gas lines without shutting down the system. For cutting and fitting pipes, tube cutters and benders provide the necessary precision and adaptability. Each of these instruments plays a crucial role in maintaining the integrity of gas lines, highlighting the importance of using appropriate tools for effective maintenance and repair.

Essential Equipment for Technicians

Technicians engaged in gas line installation and repair rely on a specific set of tools to ensure that their work meets safety and regulatory standards. A reliable gas detector is essential for identifying leaks and maintaining safe working environments. Additionally, pressure testing equipment is crucial for evaluating the integrity of gas lines. This guarantees that the installation adheres to required specifications and is free from faults that could lead to dangerous situations.

Another important piece of equipment is a pipe wrench, which allows technicians to grip and turn gas pipes securely. Calibration tools are also necessary for adjusting and setting pressure levels accurately during installation and repair jobs. Portable workstations can enhance efficiency by providing a dedicated space for technicians to store tools and perform on-site repairs. These essential pieces of equipment contribute significantly to the overall success and safety of gas line installation and repair tasks.

Testing and Monitoring Systems

Regular testing and monitoring systems are vital components of gas line installation and repair. These processes ensure that the integrity of gas lines is maintained over time. Early detection of leaks or potential failures can prevent hazardous situations and safeguard both property and lives. Routine inspections should be scheduled to assess the condition of existing lines and confirm compliance with safety standards.

Technicians employ various monitoring systems to track gas flow and pressure. Instruments such as pressure gauges and gas detectors play an essential role in identifying irregularities. Additionally, advanced technology like automatic monitoring systems can provide real-time data, enhancing response times in case of anomalies. Adopting these systems significantly contributes to effective gas line installation and repair, helping to maintain a safe environment for all users.

Techniques for Ensuring Safety

Implementing rigorous safety techniques is paramount in gas line installation and repair. Technicians should always begin by conducting thorough inspections before commencing any work. This includes checking for leaks, ensuring all valves and fittings are properly sealed, and confirming that the equipment is in good working order. Personal protective equipment (PPE) should be worn at all times, and working in well-ventilated areas is crucial to mitigate the risk of gas accumulation.

In addition to these initial precautions, ongoing monitoring during the installation and repair process plays a vital role in ensuring safety. Utilising appropriate gas detection systems can alert technicians to any potential leaks in real time. Regularly reviewing safety protocols and conducting training sessions for all staff involved in gas line installation and repair is also essential for maintaining a safety-first culture. Proper documentation and adherence to local regulations further contribute to safe practices in the field.

FAQS

Why is it important to choose qualified professionals for gas line maintenance and repair?

Choosing qualified professionals ensures that the work is performed safely and meets regulatory compliance, reducing the risk of gas leaks and other hazards.

What criteria should I consider when selecting certified technicians for gas line work?

Consider their certification, experience, reputation, and whether they follow Australian standards for safety and compliance in gas line maintenance.

What are some common tools used for gas line maintenance?

Common tools include gas leak detectors, pressure gauges, pipe wrenches, and specialised gas testing equipment designed for safe handling of gas lines.

What essential equipment should technicians have for effective gas line maintenance?

Technicians should have access to personal protective equipment (PPE), gas detection monitors, pipe inspection tools, and emergency shut-off systems.

How can testing and monitoring systems help ensure safety in gas line maintenance?

Testing and monitoring systems help identify leaks, measure pressure levels, and provide real-time data, allowing for proactive maintenance and immediate response to potential issues.