Table Of Contents

Applying Thread Sealant

Applying thread sealant is an essential step in gas line installation and repair. The sealant acts as a barrier that prevents gas leaks at the threaded joints. Start by thoroughly cleaning the threads of the pipes to remove any debris, oil, or dust. This preparation ensures that the sealant adheres properly, providing a reliable seal. When applying the sealant, ensure it is evenly distributed around the threads without excessive buildup, which could lead to complications during assembly.

After application, the threads should be aligned properly before tightening. Using the right type of thread sealant is crucial; while some recommend Teflon tape, others may prefer liquid pipe sealants specifically made for gas lines. Always check the manufacturer’s recommendations to ensure compatibility with the materials being used. This careful approach will help to achieve an effective seal, minimising the risk of leaks in the gas line system.

StepbyStep Application Process

To begin the application of thread sealant, ensure that the surfaces of the threads are clean and free from debris. This preparation is crucial for achieving a proper seal. Apply the thread sealant evenly around the male threads, ensuring complete coverage without over-applying. A thin layer is sufficient; too much can lead to complications during tightening.

Next, join the threaded components by turning them together carefully. Be mindful not to cross-thread the connections, as this can compromise the seal and lead to leaks. Following this, allow the sealant to cure according to the manufacturer's guidelines before applying any pressure to the gas line. Gas line installation and repair requires diligence to avoid safety hazards, making this step particularly important.

Tightening Techniques

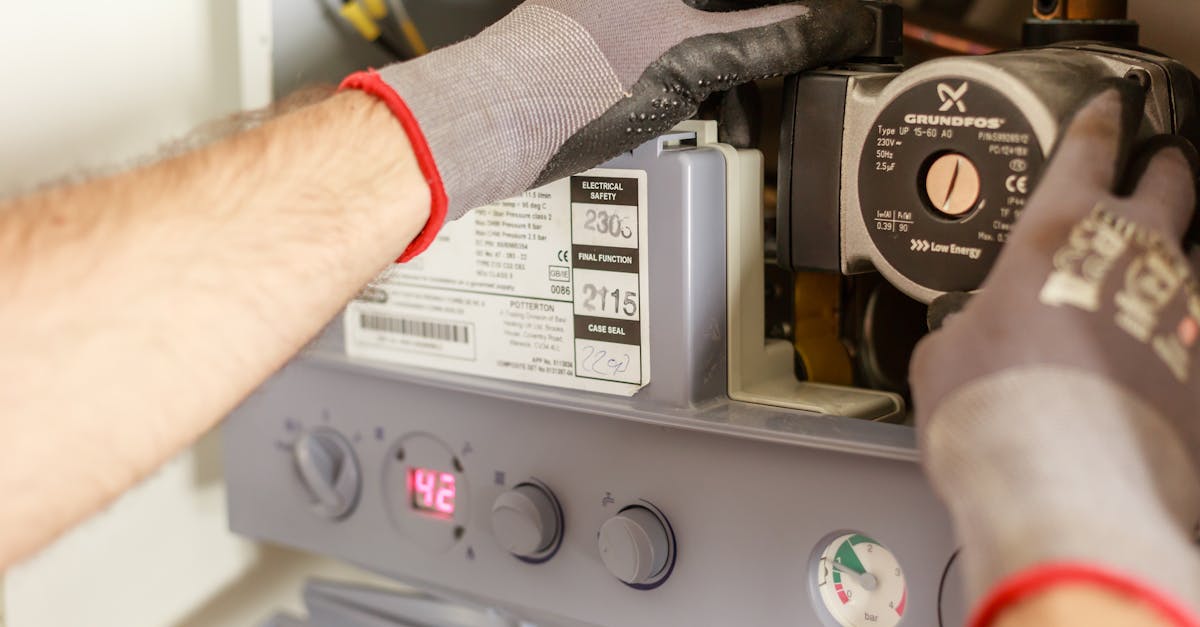

To ensure the integrity of gas line connections, proper tightening techniques are essential during installation and repair. Over-tightening can lead to thread damage or deformation, which may result in leaks. It is crucial to follow the manufacturer's specifications regarding torque to achieve the right balance. Using a torque wrench can greatly assist in achieving precise measurements and avoiding excessive force on the threads.

Gas line installation and repair also require a careful approach to the order of tightening. For connections with multiple joints, it is advisable to tighten them in a sequential manner. This helps to evenly distribute pressure across the joints, reducing the risk of strain on any single connection. Applying the right technique not only ensures safety but also enhances the longevity of the gas line fittings.

Proper Torque Specifications

Proper torque specifications are critical during gas line installation and repair to ensure that the fittings form a tight seal. Each type of fitting may have different recommended torque values, which are often provided by the manufacturer. It’s essential to refer to these specifications to avoid over-tightening, which can damage the threads or cause the fittings to deform. Conversely, insufficient torque can lead to leaks, compromising the safety of the entire gas system.

Using a torque wrench can help achieve the required specifications accurately. This tool not only helps in applying the correct amount of force but also allows for a consistent tightening pattern. It’s advisable to apply torque in a gradual manner, checking the values at intervals to ensure that the installation remains within the recommended limits. Establishing proper torque can significantly enhance the reliability of gas line connections and contribute to overall system safety.

Testing for Leaks

Leak detection is a critical step in gas line installation and repair. Ensuring that all connections are secure helps prevent potential hazards associated with gas leaks. Various methods can be employed to identify leaks, including the use of soap solution, which can create visible bubbles when applied to joints and fittings. Another reliable method involves the use of electronic leak detectors, which can sense even minute traces of gas, providing a highly accurate assessment.

After completing leak testing, it is essential to address any identified issues promptly. If bubbles appear in the soap solution or if a leak detector indicates the presence of gas, it is vital to stop the system, make necessary repairs, and retest the area. Regular maintenance and inspections help ensure the longevity and safety of gas line systems, contributing to overall safety in gas line installation and repair practices.

Methods for Leak Detection

Detecting leaks in gas lines is critical for safe operation. Various methods can be employed to identify potential issues before they escalate. One effective technique involves using a soap solution, which can be applied directly to the joints and fittings. If bubbles form, this indicates the presence of escaping gas. Visual inspection should not be overlooked; pipe corrosion or any visible damage may signal a leak that requires immediate attention.

For more advanced leak detection, a gas detector can be an invaluable tool. These devices are designed to sense specific gas types and provide readings that indicate the presence of leaks. Regular testing is crucial, particularly after gas line installation and repair, to ensure system integrity. In addition to using detection tools, maintaining a routine inspection schedule enhances safety and can prevent costly repairs down the line.

FAQS

What type of thread sealant should I use for gas lines?

It's recommended to use a thread sealant specifically designed for gas lines, such as PTFE (Teflon) tape or a liquid pipe thread sealant that is rated for gas use.

Is it necessary to apply thread sealant on gas line threads?

Yes, applying thread sealant helps to ensure a tight seal and prevent gas leaks, which is crucial for safety and efficiency in gas line installations.

How tight should I tighten gas line fittings?

It's important to follow the proper torque specifications provided by the manufacturer to avoid over-tightening, which can damage the fittings or lead to leaks.

How can I test for leaks after sealing gas line threads?

You can test for leaks by using a soap and water solution, applying it to the joints. If bubbles form, there is a leak. Alternatively, you can use a gas leak detector for a more precise measurement.

What should I do if I find a leak in my gas line after sealing?

If you discover a leak, immediately turn off the gas supply and ventilate the area. It is advisable to contact a qualified gas professional to assess and repair the issue safely.