Table Of Contents

Impact on Business Operations

Non-compliance with regulations in gas line installation and repair can significantly disrupt business operations. Companies may face costly fines, which can strain financial resources and detract from investment in other areas. Beyond immediate financial penalties, non-compliance may lead to project delays, increasing the potential for further losses. This ripple effect can hinder a company's ability to meet contractual obligations and jeopardise relationships with suppliers and customers.

Moreover, the impact on staff efficiency is notable. Workers may need to spend additional hours rectifying compliance issues or handling the administrative burden associated with penalties. This downtime reduces productivity and can lead to frustration among employees. Furthermore, if non-compliance results in accidents or hazardous situations, the implications for employee safety and morale become paramount, potentially fostering a workplace culture that prioritises compliance over operational excellence.

Reputation and Customer Trust

Reputation plays a vital role in the success of businesses involved in gas line installation and repair. Failure to comply with safety regulations can lead to significant harm, both physically and financially. Customers are becoming increasingly aware of safety standards and the qualifications of service providers. Any suggestion of negligence can damage a company's image and result in lost business opportunities. Businesses must maintain a commitment to quality and compliance to foster customer confidence.

Trust is essential in the gas line installation and repair industry. Customers need to feel secure that the work performed adheres to the highest standards of safety and reliability. A company with a history of compliance and positive customer feedback is more likely to attract new clientele. Conversely, past infractions or publicised penalties can create long-lasting misgivings about a service provider’s credibility. Building and maintaining customer trust hinges on consistently delivering safe and compliant services.

The Role of Regulatory Bodies

Regulatory bodies play a vital role in overseeing gas line installation and repair activities. They establish the necessary frameworks and standards that must be adhered to by all licensed professionals. These organisations ensure that safety protocols are followed, protecting both workers and the general public from hazards associated with improper installation or maintenance. Their involvement is crucial in enforcing compliance with regulations, which helps maintain industry integrity.

The effectiveness of regulatory bodies is significantly linked to their oversight and enforcement mechanisms. Regular audits and inspections are conducted to ensure compliance with safety and operational standards. Non-compliance can lead to serious repercussions, including fines and licence suspensions. Such measures are intended not only to penalise wrongdoing but also to incentivise companies to prioritise safe practices in gas line installation and repair, fostering an environment of accountability within the industry.

Oversight and Enforcement Mechanisms

Regulatory bodies play a crucial role in ensuring that gas line installation and repair adhere to established standards. They implement oversight mechanisms designed to monitor compliance among professionals and businesses involved in these activities. Regular inspections and audits can identify potential violations before they lead to serious incidents. These checks not only enhance safety but also serve as a deterrent against non-compliance, reinforcing the importance of following the correct procedures.

Enforcement mechanisms complement oversight by imposing penalties on those who fail to meet regulations. These penalties can range from fines to more severe sanctions, such as license suspension or revocation for repeat offenders. The rigorous application of these measures underscores the gravity of non-compliance in gas line installation and repair. By holding individuals and companies accountable, regulatory bodies aim to foster a culture of safety and responsibility within the industry.

Training and Certification Requirements

Training and certification requirements play a crucial role in ensuring safety and compliance in gas line installation and repair. Proper training equips personnel with the necessary skills to perform installations that meet regulatory standards. This knowledge helps prevent accidents that could arise from improper handling of gas lines. Moreover, certification programmes commonly assess a worker's understanding of relevant laws and practices, fostering a culture of accountability and excellence within the industry.

A well-structured training regime typically includes both theoretical and practical components. This dual approach ensures that technicians are not only knowledgeable about the regulations but also proficient in executing their tasks effectively. Furthermore, periodic re-certification is often mandated to keep professionals updated on new technologies and legislative changes. Such measures enhance the overall integrity of gas line installation and repair, ultimately safeguarding public welfare and promoting industry best practices.

Ensuring Qualified Personnel

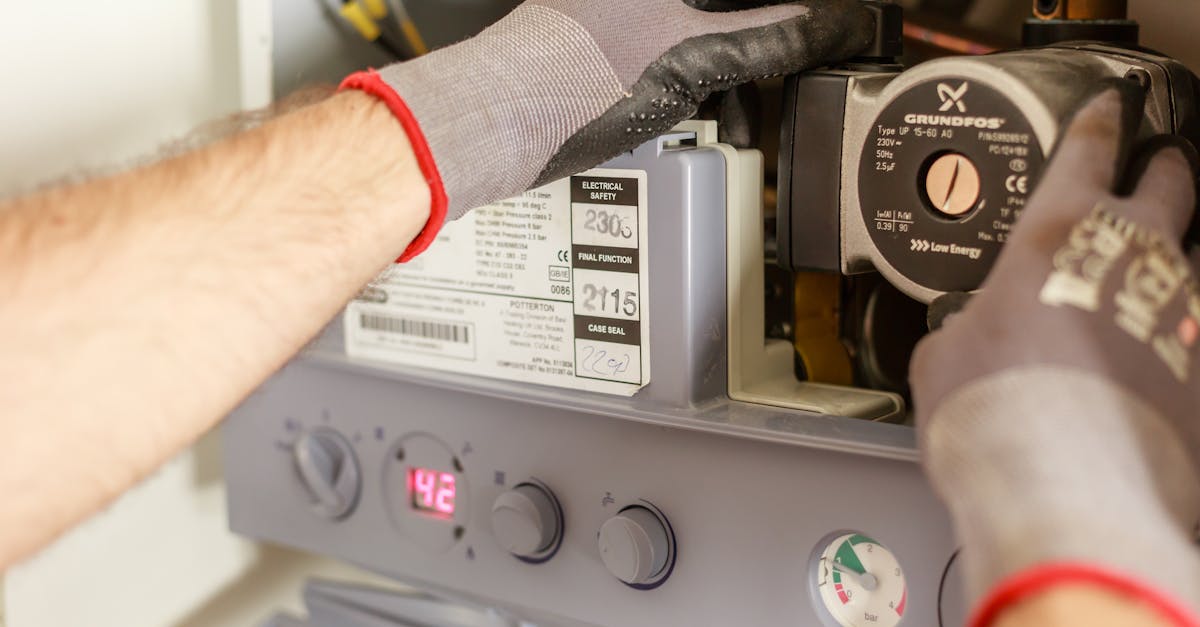

Proper training and certification of personnel involved in gas line installation and repair is vital for maintaining safety and compliance with regulations. The complexities of working with gas systems require that technicians possess a deep understanding of both technical skills and industry standards. Training programmes must be accredited by relevant authorities to ensure that participants are educated on the latest safety protocols, equipment usage, and emergency procedures.

Employers must prioritise hiring qualified personnel to perform gas line installation and repair to mitigate risks associated with non-compliance. A workforce that is well-trained reduces the potential for costly mistakes and enhances overall operational efficiency. Continuous professional development opportunities should also be offered to keep employees abreast of changes in regulations and technological advancements in the field.

FAQS

What are the potential penalties for non-compliance in gas line installations?

Penalties for non-compliance can vary widely, including fines, revocation of licenses, and legal action. In severe cases, non-compliance may lead to criminal charges, especially if it results in safety hazards or environmental damage.

How can non-compliance affect business operations in the gas line industry?

Non-compliance can lead to significant operational disruptions, including project delays, increased costs from fines, and potential loss of contracts. Additionally, it can damage relationships with stakeholders and regulatory bodies.

What impact does non-compliance have on a company's reputation and customer trust?

Non-compliance can severely harm a company's reputation, leading to a loss of customer trust. Negative publicity may arise from incidents related to non-compliance, making it challenging to retain and attract clients.

What role do regulatory bodies play in enforcing compliance in gas line installations?

Regulatory bodies are responsible for setting safety standards, conducting inspections, and enforcing compliance through oversight mechanisms. They ensure that companies adhere to established regulations to protect public safety and the environment.

What training and certification requirements exist for personnel involved in gas line installations?

Personnel must typically undergo specific training and obtain certifications in gas line installation and safety practices. This ensures that they are qualified to perform the work and comply with relevant regulations and standards.