Table Of Contents

Economic Implications for Gas Installers

Gas line installation and repair sectors are experiencing notable shifts due to new regulations. Compliance demands can impose significant financial strain on installers, as they may need to invest in updated training and equipment. These costs could ultimately affect pricing structures for consumers. The enhanced regulatory framework aims to ensure safety and environmental protection but also introduces operational challenges for gas installers who must navigate these mandatory changes.

Despite the economic pressures, there are potential benefits associated with compliance. Installers who adopt best practices in gas line installation and repair may find increased demand for their services. Consumers are becoming more environmentally conscious, leading them to prefer businesses that adhere to regulations. This shift can enhance the reputation of compliant installers, potentially resulting in steady growth and a more competitive edge in a changing market environment.

CostBenefit Analysis of Compliance

Assessing the cost-benefit analysis of compliance with new gas supply regulations involves evaluating both the financial outlay and the potential gains for gas installers. Initial investments may be required to upgrade equipment and training to meet regulatory standards. However, these costs can be offset by the long-term benefits, including improved operational efficiency and a reduction in the risk of costly penalties for non-compliance. Furthermore, adhering to regulations can enhance a company's reputation, leading to increased customer trust and loyalty.

For gas line installation and repair businesses, compliance with regulations can also open doors to new opportunities. Many clients prefer contractors who adhere to the latest standards, which can result in more contracts and higher revenue. In addition, staying ahead of regulatory changes allows companies to be more competitive in the market. By incorporating sustainable practices and technology, these businesses not only meet compliance requirements but also contribute positively to the industry’s image, fostering a more environmentally responsible future.

Environmental Considerations

The gas supply regulation introduces significant environmental considerations that impact the approach to gas line installation and repair. By enforcing stricter standards, these regulations encourage better practices among installers, which ultimately leads to reduced emissions and lower risk of leaks. The emphasis on sustainable practices can result in a more efficient use of resources, aligning with broader environmental goals set by governmental policies and community expectations.

Additionally, compliance with such regulations often necessitates the adoption of greener technologies and methods in gas line installation and repair. This fosters innovation within the industry, as businesses seek out eco-friendly solutions that not only meet legal requirements but also enhance their reputation among environmentally conscious consumers. Ongoing training and the integration of sustainable techniques in gas service can significantly contribute to reducing the carbon footprint, ensuring that both current and future needs are met without compromising ecological integrity.

Promoting Sustainable Gas Use

Sustainable gas use is increasingly becoming a priority as regulations evolve. This shift encourages gas installers to adopt practices that not only comply with legal requirements but also promote environmental stewardship. Adopting technologies like energy-efficient appliances can significantly reduce emissions associated with gas consumption. Moreover, using renewable gas variants, such as biogas or synthetic natural gas, contributes to a more sustainable energy mix.

Gas line installation and repair must also embrace sustainability principles. Training programmes for installers can help them understand the benefits of eco-friendly practices, which align with evolving consumer expectations. Encouraging the use of materials that minimise environmental impact during installations reinforces the commitment to sustainable practices. This proactive approach can enhance the reputation of gas installation services while making a meaningful contribution to reducing the carbon footprint of gas usage.

Technological Advances in Gas Installations

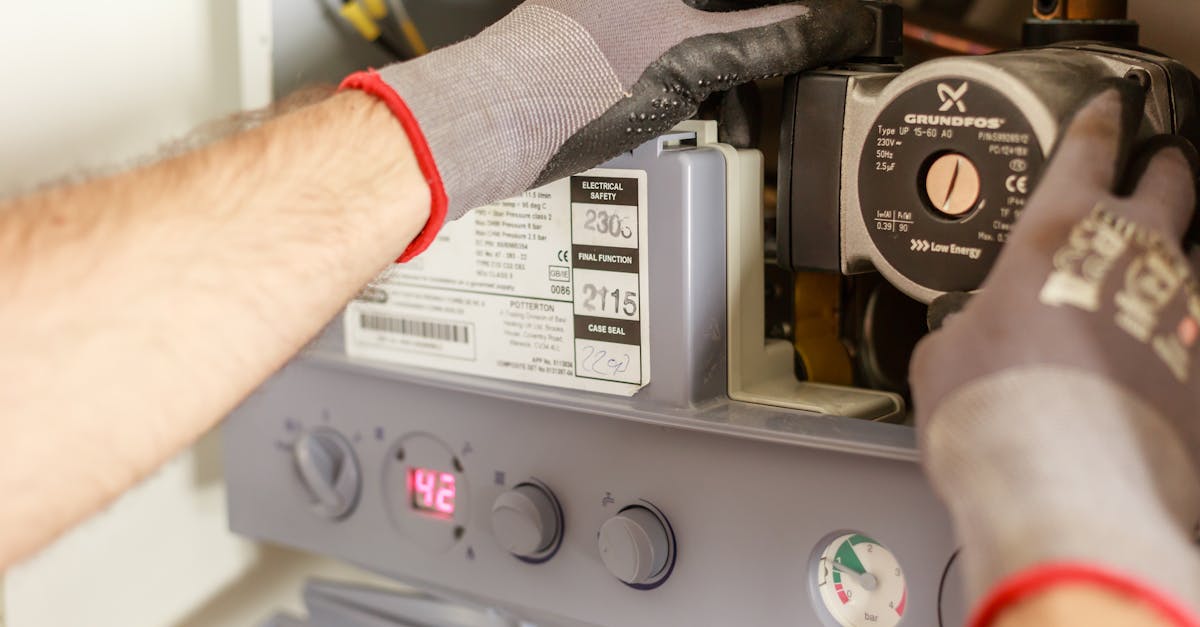

Recent advancements in technology have significantly transformed the landscape of gas installations. The introduction of smart monitoring systems enhances the efficiency of gas line installation and repair, allowing technicians to detect leaks and malfunctions quickly. These innovations not only reduce the time required for maintenance but also minimise safety risks. With the help of predictive analytics, installers can anticipate potential issues before they escalate, ensuring system reliability and longevity.

Furthermore, the integration of automation in gas installations has streamlined processes and improved accuracy. Automated machinery assists in laying pipes and fittings with precision, reducing human error during installation. Consequently, such technological progress supports compliance with regulations while optimising resource use. This shift towards a more tech-savvy approach fosters a culture of safety and sustainability within the gas industry, reinforcing the importance of well-regulated practices in gas line installation and repair.

Innovations Driving Compliance

Technological advancements play a pivotal role in ensuring compliance with new gas supply regulations. Innovations such as smart sensors and automated monitoring systems are now integral to the processes involved. These technologies provide real-time data, allowing installers to detect potential leaks or safety issues promptly. As a result, businesses can enhance their operational efficiency while meeting regulatory obligations. The integration of digital platforms for reporting enables gas line installation and repair professionals to maintain accurate records and streamline their compliance efforts with minimal disruption to their services.

Additionally, the development of advanced materials has significant implications for gas installations. New composite materials offer increased durability and resistance to corrosion, which helps to extend the lifespan of gas lines. These improvements not only reduce the need for frequent repairs but also align with sustainability goals by minimising waste. Implementing such innovations encourages a proactive approach in the industry, facilitating compliance with stricter regulations while ensuring safety and reliability in gas line installation and repair.

FAQS

What are the main economic implications of the Gas Supply Regulation for gas installers?

The Gas Supply Regulation can create both challenges and opportunities for gas installers, as they may face increased compliance costs but also benefit from enhanced market stability and potential funding for upgrades.

How does a cost-benefit analysis help in understanding compliance with the Gas Supply Regulation?

A cost-benefit analysis evaluates the financial impacts of compliance against the potential risks and penalties of non-compliance, helping installers to make informed decisions about investing in necessary upgrades and technologies.

What environmental considerations are associated with the Gas Supply Regulation?

The regulation promotes the responsible use of gas, aiming to reduce emissions and encourage sustainable practices among gas installers, thereby contributing to broader environmental protection goals.

How does the Gas Supply Regulation promote sustainable gas use?

The regulation encourages practices that minimise waste and emissions, supports the adoption of renewable gas sources, and drives the development of technologies that enhance energy efficiency in installations.

What technological advances are influencing gas installations under the new regulation?

Innovations such as smart metering, advanced leak detection systems, and improved gas utilisation technologies are emerging in response to the regulation, helping installers meet compliance requirements and enhance operational efficiency.