Table Of Contents

The Audit Process

The audit process for gas line installation and repair involves a systematic approach that ensures compliance with safety standards. Initially, auditors prepare by reviewing relevant regulations and company policies. Documentation is gathered, outlining previous audits and maintenance records. This groundwork sets the stage for thorough inspections.

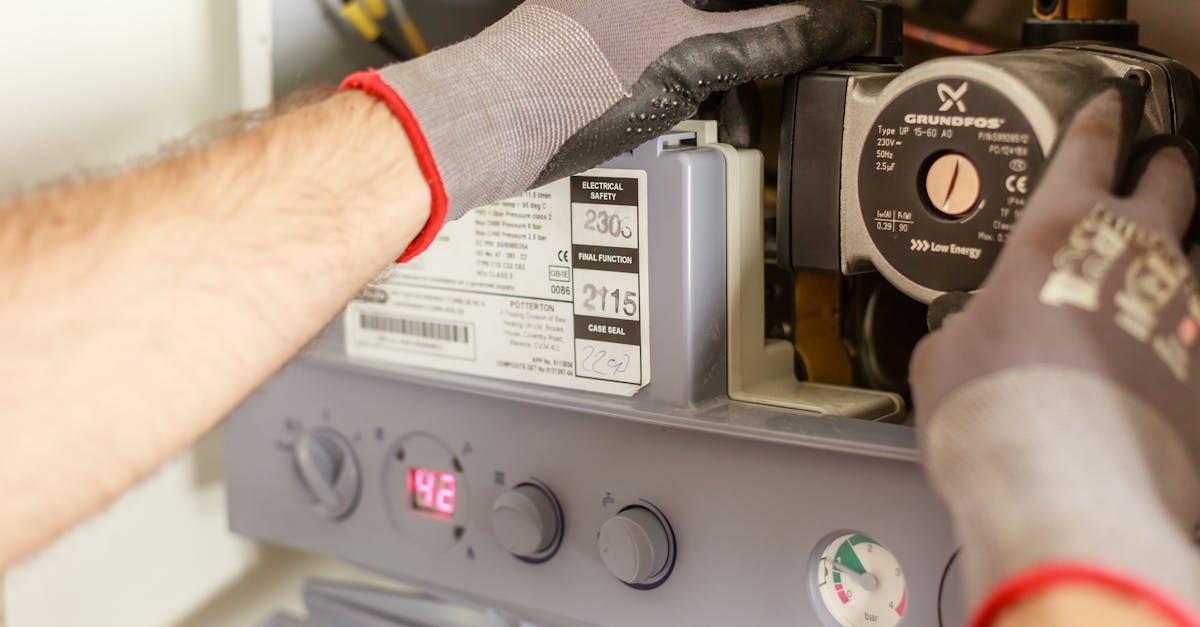

During the implementation phase, auditors conduct physical inspections of the gas lines and associated equipment. They assess the condition of the infrastructure and the adherence to safety protocols. Interviews with personnel are conducted to evaluate their understanding of safety measures and procedures. Overall, this comprehensive review plays a crucial role in identifying potential hazards and improving safety practices within the industry.

From Planning to Implementation

The planning phase of safety audits in gas line installation and repair involves a thorough assessment of the site to identify potential hazards and compliance requirements. Auditors typically gather relevant documentation, review previous reports, and consult with on-site personnel to understand ongoing operations. This initial groundwork is crucial as it sets the stage for a comprehensive audit that can effectively pinpoint areas requiring attention.

Once the planning is complete, the implementation phase begins, where auditors conduct their evaluations according to established checklists and procedures. They observe operational practices, inspect equipment, and engage with staff to ensure adherence to safety protocols. This hands-on approach allows for a robust examination of processes currently in place, highlighting both strengths and areas that may need improvement in gas line installation and repair.

Role of Technology in Safety Audits

Technology plays a vital role in enhancing the efficiency and effectiveness of safety audits in gas line installation and repair. Advanced software solutions facilitate real-time data collection and analysis. This capability ensures that auditors can accurately track compliance with safety regulations. Furthermore, the integration of mobile applications allows for quick reporting and auditing, streamlining the process and ensuring that potential risks are identified promptly.

Innovative tools such as drones and sensors have transformed how safety audits are conducted in gas line installation and repair. Drones provide a unique vantage point, allowing inspectors to survey hard-to-reach areas without significant disruption to operations. Meanwhile, sensors can detect leaks and other hazards more effectively than traditional methods. Embracing these technologies not only enhances the accuracy of audits but also contributes to a safer working environment.

Innovative Tools and Techniques

The integration of advanced technologies into safety audits is transforming the landscape of gas line installation and repair. Methods such as infrared thermography can identify leaks and weaknesses in pipelines by detecting temperature variations, which are often indicative of gas escaping. Additionally, drones equipped with high-resolution cameras can survey vast stretches of pipeline more efficiently than traditional methods, ensuring comprehensive inspections while maintaining safety.

Software tools also play a critical role in enhancing the audit process. Applications designed for data collection and analysis allow auditors to record findings in real time, facilitating prompt decision-making. These tools can generate detailed reports and visualisation of data trends over time, providing insights that help to prevent potential hazards during gas line installation and repair. Utilising these innovative resources not only increases the effectiveness of audits but also contributes to an overall culture of safety in the industry.

Training and Certification for Auditors

Ensuring that auditors possess the necessary training and certification is crucial for maintaining safety standards in gas line installation and repair. Qualified auditors undergo comprehensive training programmes that cover regulatory requirements, risk assessments, and the specific practices related to gas systems. These programmes encourage a thorough understanding of the complexities involved in gas line work, thus enhancing the effectiveness of safety audits.

Certification ensures that auditors not only meet the minimum competency requirements but also stay updated with ongoing changes in regulations and technology. Continuous professional development is vital due to the evolving nature of safety standards in gas line installation and repair. Companies often prioritise hiring certified auditors to guarantee adherence to stringent safety protocols, fostering trust and accountability within the industry.

Ensuring Competency and Expertise

To ensure competency and expertise in the field of gas line installation and repair, it is crucial for auditors to undergo rigorous training and certification programs. These programmes provide a comprehensive understanding of safety regulations, industry best practices, and the specific challenges associated with gas line work. Knowledge gained through both theoretical coursework and practical experience equips auditors to effectively identify potential hazards and implement corrective measures to maintain safety standards.

Additionally, ongoing professional development is essential for auditors to keep their skills current amid evolving industry standards and technologies. Workshops, seminars, and refresher courses enable auditors to stay updated on the latest techniques in gas line installation and repair. This commitment to continuous education reinforces the importance of maintaining a high level of expertise, ultimately contributing to safer work environments and reducing the risks associated with gas line operations.

FAQS

What is a safety audit in gas line work?

A safety audit in gas line work is a systematic evaluation of safety procedures, practices, and compliance with regulations to identify potential hazards and ensure the safe operation of gas lines.

Why are safety audits important in the gas industry?

Safety audits are crucial in the gas industry as they help prevent accidents, ensure compliance with safety regulations, and protect both workers and the public from potential gas-related hazards.

What are the main steps involved in the audit process?

The main steps in the audit process include planning the audit, conducting the audit by collecting data and observing practices, analysing the findings, and implementing necessary improvements based on the audit results.

How does technology enhance safety audits in gas line work?

Technology enhances safety audits by providing innovative tools and techniques, such as digital inspection software, drones for aerial surveys, and data analytics, which improve the accuracy and efficiency of the audit process.

What qualifications do safety auditors need?

Safety auditors typically require relevant training and certification in safety management or industrial safety, along with significant experience in the gas industry to ensure they possess the necessary competency and expertise.