Table Of Contents

Inspections and Assessments

Inspections and assessments form a crucial part of ensuring that gas line installation and repair meet regulatory and safety standards. These processes typically involve a thorough examination of the proposed installation site, checking for compliance with relevant codes and regulations. Inspectors assess various factors, including the materials used, the design of the installation, and any potential hazards that may arise from improper setup. This scrutiny is crucial in preventing accidents and ensuring both operational efficiency and safety in gas delivery.

Once the initial inspections are completed, further assessments may be necessary to address any identified deficiencies or to ensure compliance with specific regulations. Inspectors will often provide a detailed report outlining their findings and may require additional documentation or modifications to the installation plans. It is essential for applicants to remain engaged throughout this stage, addressing any issues promptly to avoid delays. Ensuring a smooth inspection and assessment process contributes significantly to the overall success of gas line installation and repair projects.

What to Expect During the Inspection Process

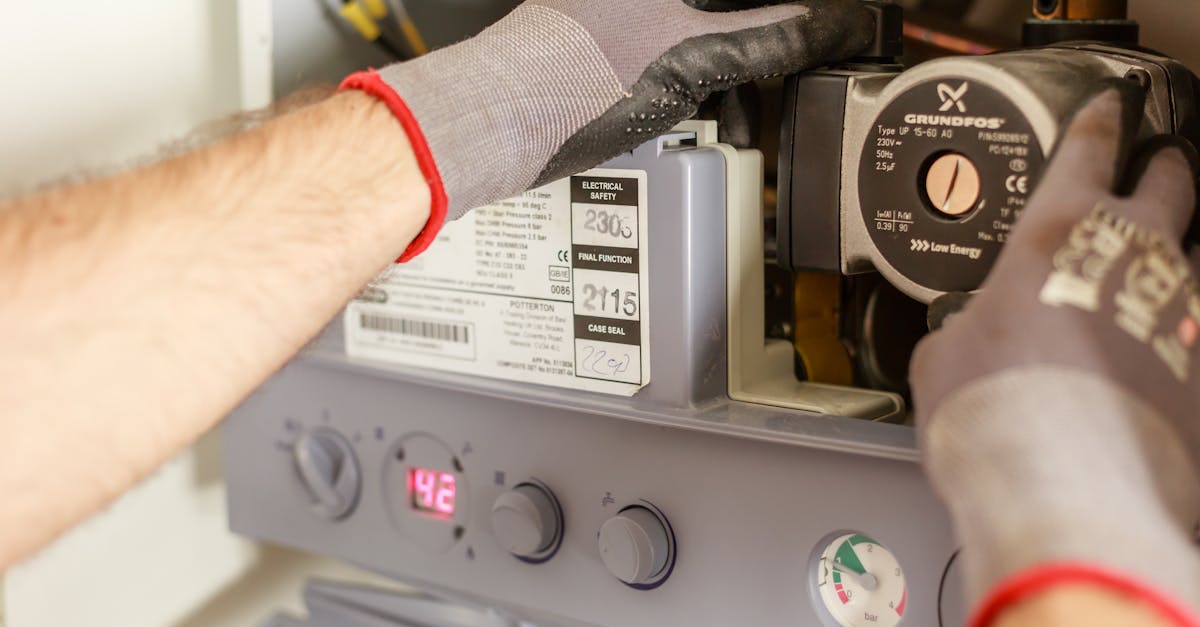

During the inspection process for gas line installation and repair, you should expect a thorough examination of the work completed. An inspector will assess adherence to safety regulations and building codes. They will check the physical condition of the gas lines, valves, and any associated fittings. Proper testing will also be conducted to ensure there are no leaks. This process typically involves both visual inspections and functional tests to confirm that the installation meets industry standards.

It's essential to prepare your site for the inspector's arrival. Ensure that all areas of the gas line installation and repair are easily accessible to facilitate a comprehensive review. Any documentation related to your project, such as permits and previous inspection reports, should be readily available for the inspector’s scrutiny. This openness not only aids the inspector but also helps in fostering trust and transparency in the process.

Addressing Compliance Issues

Compliance issues during the approval process for gas line installation and repair can arise from various factors. Authorities expect strict adherence to legislation and safety standards. Submissions frequently encounter problems when documentation is incomplete or insufficiently detailed. For instance, failure to provide accurate plans or specifications may lead to significant delays or outright rejections. Ensuring that all paperwork is thorough and correct is essential for moving the process forward.

Once compliance issues are identified, applicants must act promptly to rectify them. This often involves engaging with the relevant regulatory bodies to understand specific requirements. Furthermore, it may also require additional inspections or assessments to verify that proposed gas line installations meet safety regulations. By proactively addressing these issues, applicants can streamline the approval process and minimise disruptions to their projects.

Common Reasons for Application Rejections

Applications for gas installations can be rejected for several reasons, often related to safety and compliance issues. One common reason involves inadequate documentation, such as missing details about the gas line installation and repair plans. If the submitted plans lack clarity or fail to meet the specific requirements set forth by regulatory bodies, approval may be denied. Moreover, applications that do not include evidence of gas compliance certificates or the qualification of the contractors involved can lead to rejections.

Another frequent cause for application rejection is the failure to address potential hazards during the installation process. If the proposed gas line installation and repair does not adequately mitigate risks associated with leaks or structural integrity, the application may not meet safety standards. Additionally, any inconsistencies between local regulations and the proposed work can lead to complications, highlighting the importance of thorough research and adherence to guidelines prior to submission.

Timeline for Approval Process

The timeline for the approval process of gas line installation and repair can vary based on several factors. Typically, the stages include initial application submission, inspections, and final approvals from local authorities. Each stage may take a different amount of time depending on the complexity of the installation, existing infrastructure, and compliance with safety regulations. It is advisable to allow for potential delays, particularly in busy periods when the demand for inspections may be heightened.

Additionally, the completeness of the submitted documentation plays a significant role in determining processing times. Inaccurate or insufficient information can lead to delays in obtaining approval. It's important to ensure that all relevant details are provided accurately in the application to avoid unnecessary setbacks. This proactive approach not only streamlines the process but also helps in meeting the required timelines more effectively.

Factors Affecting Processing Times

Processing times for gas installation approvals can vary based on several key factors. One of the primary influences is the accuracy and completeness of the submitted documentation. Applications that lack required information can face delays as authorities seek clarification or additional details, prolonging the overall process. Furthermore, the type of installation requested can impact the speed of approval. More complex projects tend to require more thorough reviews, which can extend timelines significantly.

Another crucial factor is the workload and availability of relevant authorities. During peak times, when many applications are being processed simultaneously, delays may occur due to limited resources. Additionally, any required inspections or assessments for gas line installation and repair can also extend approval times, especially if scheduling conflicts arise or if inspectors need to address multiple sites. Effective communication between applicants and regulatory bodies can help mitigate some of these delays.

FAQS

What does the inspection process for gas installations involve?

The inspection process typically involves a thorough assessment of the installation to ensure it meets safety and regulatory standards. Inspectors will check the gas appliances, piping, and ventilation systems, and may also conduct pressure tests.

How can I prepare for a gas installation inspection?

To prepare for a gas installation inspection, ensure that all work is complete and accessible. It’s also helpful to have relevant documentation, such as installation permits and compliance certificates, readily available for the inspector.

What are some common reasons for rejection of gas installation applications?

Common reasons for rejection include incomplete applications, failure to meet safety standards, lack of proper documentation, or non-compliance with local regulations. It’s important to double-check all requirements before submission.

How long does it typically take to get approval for a gas installation?

The timeline for approval can vary significantly based on factors like the complexity of the installation, the workload of the regulatory body, and any compliance issues that may arise. Generally, it can take anywhere from a few weeks to several months.

Are there any fees associated with the gas installation approval process?

Yes, there are often fees associated with the gas installation approval process, including application fees, inspection fees, and possibly additional costs for re-inspections. It’s advisable to check with your local authority for specific fee structures.