Table Of Contents

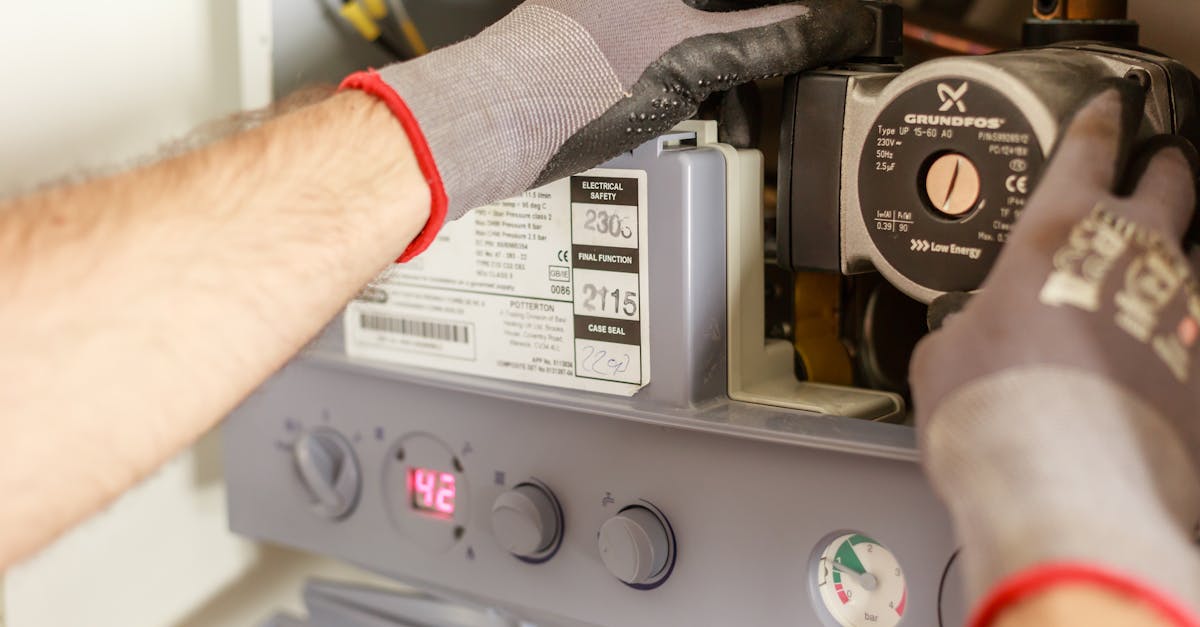

Inspection and Testing Records

Inspection and testing records are crucial components in the documentation process for pipe installation and repair. These records not only serve as evidence of compliance with regulatory standards but also provide detailed insights into the condition and performance of the installed systems. They typically include information on various tests performed, such as pressure tests, leak detection tests, and any inspections carried out throughout the installation process. Detailed logs facilitate accountability and ensure that any issues identified can be addressed promptly, ensuring safety and longevity in infrastructure.

Maintaining accurate and comprehensive inspection and testing records also plays a significant role in future maintenance and upgrades. These documents enable contractors and engineers to assess historical data when planning for modifications or repairs, leading to better decision-making. Additionally, they can serve as a reference point during audits or inspections by governing authorities, helping to demonstrate adherence to industry standards. Accurate records ultimately contribute to a seamless pipe installation and repair process, fostering trust among stakeholders involved in the project.

Importance of Documenting Compliance Checks

Documenting compliance checks during pipe installation and repair is crucial for ensuring that all procedures align with industry standards and regulatory requirements. These records serve as a tangible proof of adherence to safety protocols and best practices. They not only provide a reliable reference for future inspections but also enhance the accountability of the teams involved. Documentation acts as a safeguard against potential liabilities, assisting in demonstrating compliance to regulatory bodies or clients when required.

Moreover, thorough documentation supports continuous improvement within the project lifecycle. By tracking compliance checks, companies can identify recurring issues and address them proactively, ultimately minimising risks associated with pipe installation and repair. This informative approach fosters a culture of safety and diligence, benefiting workers and stakeholders alike. Properly maintained records can also streamline audits and inspections, facilitating smoother operations and reinforcing the commitment to excellence in all aspects of the project.

Environmental Considerations in Documentation

Environmental considerations play a crucial role in the documentation process for pipe installation and repair. Detailed records help ensure compliance with local regulations that protect the surrounding ecosystem. This includes capturing data on the materials used, their environmental impact, and any mitigation measures taken to reduce harm during the installation process. Accurate documentation not only supports regulatory compliance but also enhances transparency for stakeholders involved in the project.

Managing impact assessments is essential for demonstrating due diligence in environmental protection. Proper documentation of assessments facilitates the identification of potential risks related to pipe installation and repair. This proactive approach allows companies to address issues early in the planning stage, which can lead to more sustainable practices and better community relations. Effective management of these documents creates a framework for ongoing monitoring and improvement in environmental performance.

Managing Impact Assessments

Impact assessments play a crucial role in the context of pipe installation and repair. They help identify potential environmental and social consequences related to the project. Thorough assessments consider factors such as local ecosystems, water resources, and community engagement. Proper documentation of these evaluations ensures compliance with regulations and facilitates transparency during the installation process.

Incorporating feedback from stakeholders is essential when managing impact assessments. Engaging local communities can provide insights into potential concerns and enhance the overall project approach. Collecting this information allows for a comprehensive understanding of how pipe installation and repair can affect the surrounding area. By prioritising detailed impact assessments, companies can demonstrate their commitment to environmental stewardship and community well-being.

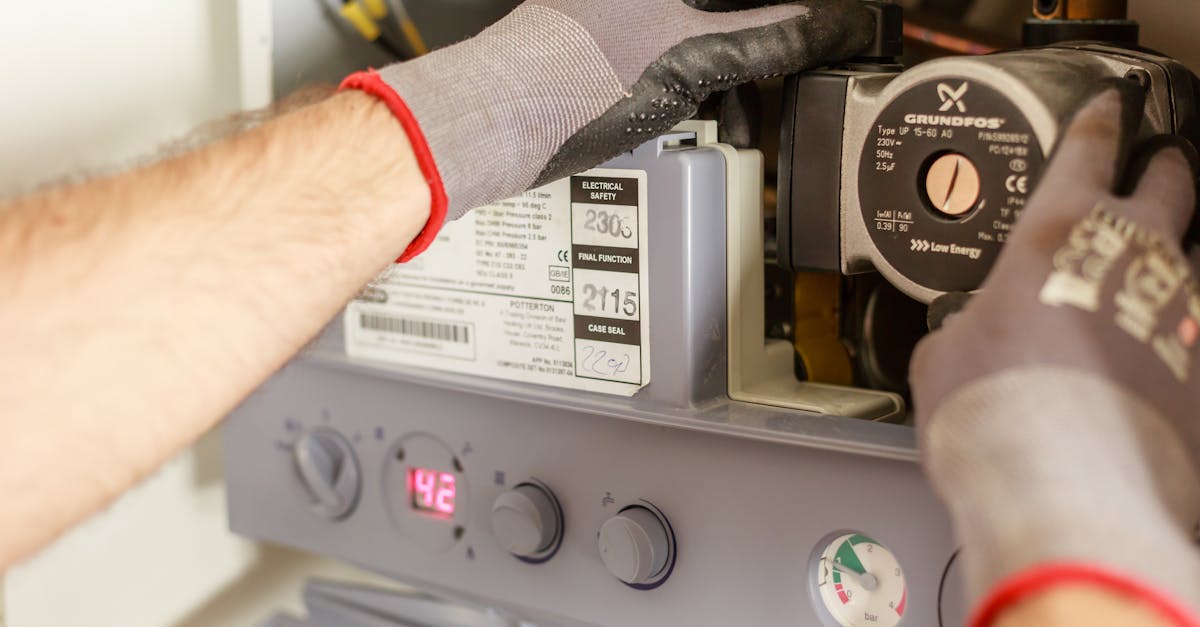

Safety Data Sheets (SDS)

Safety Data Sheets (SDS) play a crucial role in the handling and management of materials used in pipe installation and repair. They provide essential information regarding the hazards associated with specific substances, helping to ensure that workers are fully informed before engaging with these materials. This documentation outlines safety measures, emergency contacts, and first aid procedures, offering guidance that can prevent accidents and injuries during the installation process.

In the context of compliance, SDS are indispensable for demonstrating adherence to health and safety regulations. They not only aid in training personnel about the correct handling of chemicals but also ensure that all safety protocols are consistently followed. By maintaining up-to-date SDS, companies can mitigate risks associated with the misuse of hazardous materials, thereby promoting a safer workplace for everyone involved in pipe installation and repair.

Importance in Handling Pipe Materials

Proper handling of pipe materials is crucial in ensuring safety and compliance during pipe installation and repair. Safety Data Sheets (SDS) provide essential information about the physical and chemical properties of materials, highlighting potential hazards. Workers must be familiar with these documents to understand the risks associated with various substances, including proper storage and disposal methods. Ensuring that all team members are adequately trained in handling techniques not only minimises the risk of accidents but also adheres to regulatory standards.

In addition to safety, effective handling practices contribute to the longevity and performance of the pipes themselves. Environmental conditions can affect material integrity; thus, maintaining documentation related to the handling processes becomes essential. This includes tracking storage conditions, transportation methods, and any incidents of damage. Comprehensive records support compliance with industry regulations and promote accountability throughout the pipe installation and repair process.

FAQS

What types of inspection and testing records are required for pipe installation compliance?

For pipe installation compliance, it's essential to maintain records of all inspections, tests performed, and their results, including pressure tests, weld inspections, and material verifications. These documents ensure that the installation meets regulatory standards and specifications.

Why is documenting compliance checks important?

Documenting compliance checks is crucial as it provides evidence that all necessary safety, environmental, and regulatory standards have been met. This documentation can be vital in case of audits, inspections, or disputes, helping to ensure accountability and transparency in the installation process.

What are some key environmental considerations in documentation for pipe installation?

Key environmental considerations include assessing the potential impact of the installation on local ecosystems, documenting waste management practices, and ensuring compliance with environmental regulations. This includes managing any pollution risks and maintaining accurate records of environmental assessments.

How do I manage impact assessments for pipe installation?

Managing impact assessments involves conducting thorough evaluations of how the installation might affect the environment, community, and surrounding infrastructure. This includes documenting findings, implementing mitigation strategies, and keeping records of stakeholder consultations to ensure compliance with environmental standards.

Why are Safety Data Sheets (SDS) important in handling pipe materials?

Safety Data Sheets (SDS) are critical as they contain information on the properties of pipe materials, including hazards, handling guidelines, and emergency measures. Having SDS readily available ensures that workers are informed about the risks and safety practices associated with the materials being used, promoting a safe work environment.