Table Of Contents

Emergency Response Protocols

Emergency response protocols play a critical role in ensuring the safety of workers during pipe installation and repair activities. These protocols should include detailed procedures for identifying potential hazards and responding effectively to emergencies. Training should cover various scenarios, from equipment malfunctions to sudden leaks. Having clear communication channels in place is essential for coordinating a prompt response.

In addition to having established protocols, it is important that all workers are familiar with the specific emergency procedures relevant to the site. Regular drills should be conducted to reinforce knowledge and preparedness. Accessibility to emergency equipment, such as spill kits and first aid supplies, should also be prioritized. These measures enhance the overall safety culture and contribute to a more efficient response to any unforeseen incidents that may arise during pipe installation and repair.

Preparing for Accidents in the Field

Pipe installation and repair can present various risks, highlighting the importance of preparation for potential accidents. Workers must have access to well-stocked first aid kits and be trained in administering basic first aid. Safety drills should be conducted regularly to ensure that all team members understand their roles in the event of an emergency. Clear communication channels must be established so that any incidents can be reported promptly, facilitating a rapid response.

Proper signage and barriers should mark hazardous areas to alert team members and bystanders. It is essential to have emergency contact numbers readily available and to establish a designated meeting point for accountability. Regular reviews of safety protocols and the condition of equipment can also help mitigate risks associated with pipe installation and repair. Being prepared not only enhances safety but also fosters a culture of responsibility among workers on site.

Training and Competency Requirements

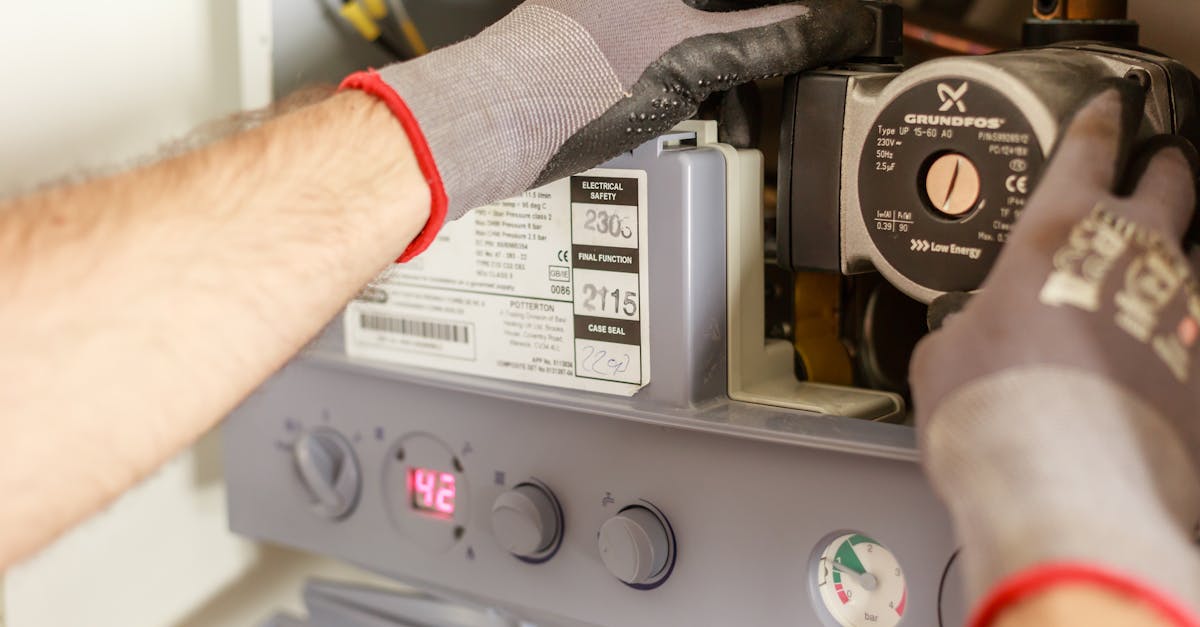

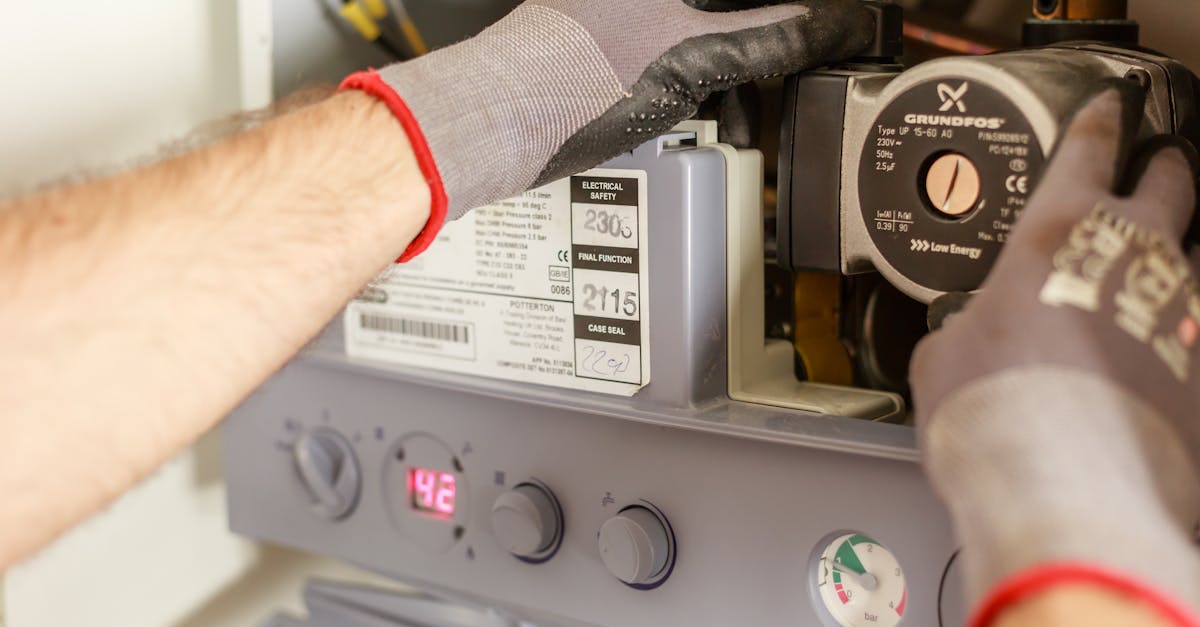

Training and competency requirements play a crucial role in ensuring that personnel involved in pipe installation and repair are adequately equipped for their tasks. Workers must undergo specific training to understand the various materials, technologies, and methods relevant to the industry. Certifications should be obtained from recognised training organisations, covering both theoretical knowledge and practical skills. Continual professional development is necessary to keep up with evolving standards and technologies in the field.

It is essential that all workers have a solid grasp of safety protocols and best practices before engaging in practical work. This includes understanding risk assessment procedures, equipment operation, and emergency response planning. By prioritising comprehensive training, companies can help mitigate risks and ensure that all employees possess the requisite competencies to carry out pipe installation and repair safely and effectively.

Ensuring Workers Are Properly Qualified

Ensuring workers are properly qualified for tasks involving pipe installation and repair is essential for maintaining safety standards and minimising risks on the job. Adequate training equips workers with the necessary skills and knowledge to handle complex situations that may arise during repairs. Certifications in specific techniques and materials relevant to pipe installation further enhance their competency, helping to ensure that installations adhere to regulatory requirements.

Regular assessments and refresher courses play a critical role in sustaining a high level of proficiency among workers. Implementing a system for ongoing education mitigates the potential for knowledge gaps that may develop over time. Encouraging employees to stay updated on the latest industry practices and safety regulations ensures that they remain proficient and compliant. This commitment to training underpins the overall effectiveness of pipe installation and repair operations.

Environmental Considerations

Environmental considerations play a critical role in the process of pipe installation and repair. The potential impact on local ecosystems must be assessed prior to any work being undertaken. Identifying sensitive areas or endangered species in proximity can help in devising suitable strategies to mitigate adverse effects. Proper site inspections should be conducted to understand how the activities may influence soil, water, and surrounding wildlife.

Waste management is another crucial aspect during pipe installation and repair. Effective strategies for handling and disposing of hazardous materials can prevent pollution and protect the environment. Containment systems and appropriate waste disposal methods ensure that any by-products are managed responsibly. Additionally, workers should be educated on the importance of minimising their environmental footprint throughout the repair process.

Managing Waste and Pollution During Repairs

Managing waste and pollution during pipe installation and repair is crucial for minimising environmental impact. Proper procedures should be established for the handling and disposal of waste materials. This includes utilising designated containers for hazardous substances and ensuring that these are clearly labelled to prevent accidental exposure. Implementing a robust waste management plan can help streamline the disposal process and promote recycling where possible.

Furthermore, workers must be trained to recognise potential sources of pollution and respond effectively. This training should encompass not only the safe disposal of materials but also measures to prevent spills and leaks during repair activities. Adopting environmentally friendly products and techniques can significantly reduce pollution, ensuring that pipe installation and repair activities comply with local regulations and standards.

FAQS

What are the key emergency response protocols for pipe repairs?

Key emergency response protocols include having a designated emergency response team, conducting regular drills, ensuring quick access to first aid supplies, and establishing clear communication channels for reporting incidents.

How can workers prepare for accidents in the field?

Workers can prepare for accidents by receiving proper training, familiarising themselves with emergency procedures, carrying necessary safety equipment, and ensuring that communication devices are accessible and functional.

What training and competency requirements are necessary for pipe repair workers?

Training and competency requirements typically include completing relevant vocational training, obtaining necessary certifications, participating in ongoing professional development, and demonstrating practical skills in a supervised environment.

How do environmental considerations impact pipe repairs?

Environmental considerations impact pipe repairs by necessitating the management of waste materials, minimising pollution, ensuring compliance with environmental regulations, and implementing practices that protect local ecosystems during repair activities.

What steps should be taken to manage waste and pollution during pipe repairs?

Steps to manage waste and pollution include conducting environmental assessments, using eco-friendly materials, ensuring proper disposal of hazardous waste, preventing spills, and following all relevant legislation and best practices for environmental protection.