Table Of Contents

Environmental Considerations

The environmental considerations associated with pipe installation and repair are paramount in preventing long-term damage to ecosystems. Non-compliance can result in leaks and spills of harmful substances, leading to soil and water contamination. Sensitive habitats may be disrupted, affecting local wildlife and biodiversity. It is essential for professionals in the industry to prioritise environmentally friendly practices while adhering to regulations.

Many regulations are established to mitigate the impacts of non-compliant installations. These measures promote not only the integrity of the infrastructure but also the health of the surrounding environment. Proper pipe installation and repair must take into account factors such as local ecosystems, potential risks, and sustainable practices. By doing so, the industry can help ensure that natural resources are protected for future generations.

Harmful Effects of NonCompliant Installations

Non-compliance in pipe installation and repair can lead to significant environmental damage. Failing to adhere to regulations may result in leaks and spills that contaminate soil and water sources. Additionally, improper installation techniques can cause structural failures, leading to costly repairs and environmental remediation efforts. The leakage of hazardous materials into ecosystems poses risks not only to wildlife but also to human populations relying on these natural resources.

The repercussions of non-compliance extend to economic implications as well. Poorly executed pipe installation and repair can necessitate frequent maintenance, increasing operational costs for businesses and municipalities. Unplanned downtimes may disrupt service delivery, causing inconvenience and frustration for users. Moreover, there is a potential for legal consequences, including fines or penalties, for violating installation standards and regulations. These factors highlight the critical need for rigorous compliance in all aspects of pipe work.

Importance of Quality Assurance

Quality assurance plays a critical role in the field of pipe installation and repair. Implementing rigorous quality assurance protocols ensures that all stages of the installation process conform to regulatory standards and best practices. This systematic approach not only enhances the durability and functionality of the pipes but also mitigates the risk of future failures. When quality assurance is prioritised, it establishes an environment where safety and efficiency are paramount.

Furthermore, regular assessments and evaluations are integral to maintaining high standards. Inspections conducted during and after the installation process can identify potential issues before they escalate into significant problems. This proactive stance not only protects the integrity of the infrastructure but also safeguards the health of the environment. By embedding a culture of quality assurance within the pipe installation and repair industry, professionals can contribute to more sustainable and reliable outcomes.

Role of Inspections in Maintaining Standards

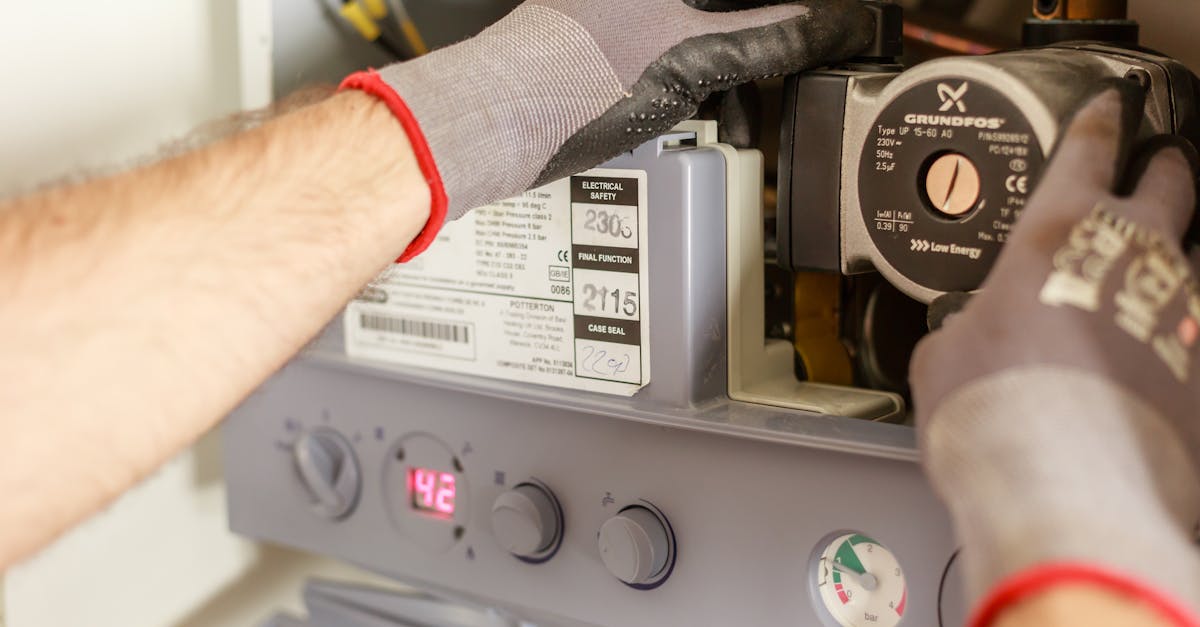

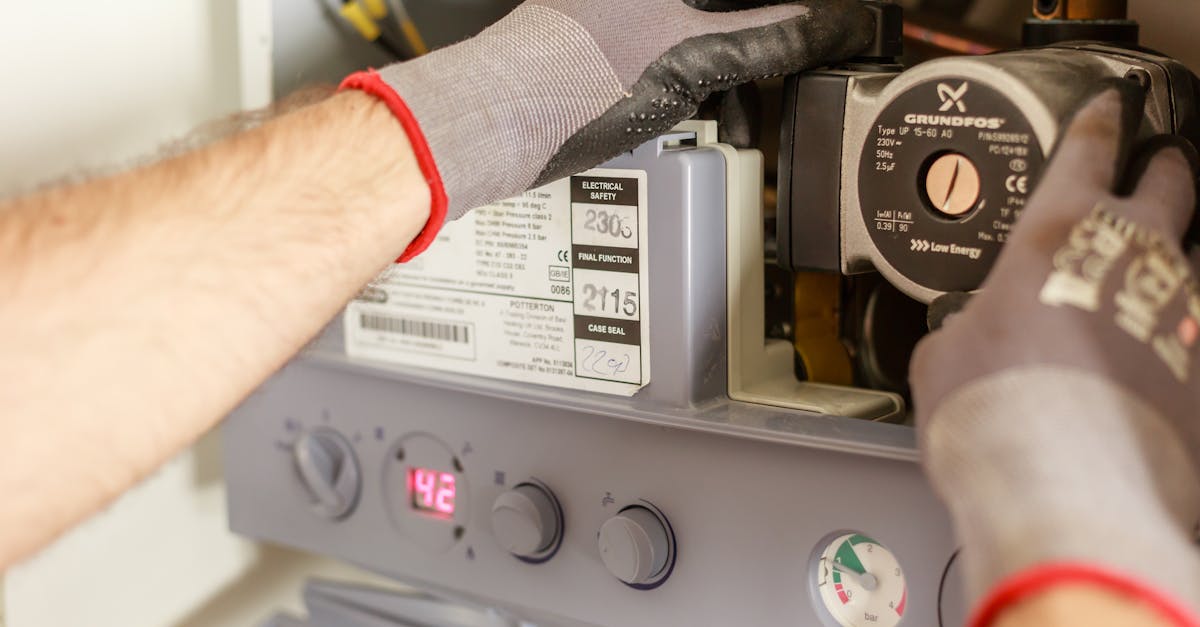

Inspections play a crucial role in ensuring that pipe installation and repair meet the required standards. Regular assessments help to identify any deviations from best practices, allowing for prompt rectification. These inspections are essential not only for conforming to regulations but also for ensuring the integrity and longevity of the installed systems. Proper oversight can prevent costly repairs and potential environmental hazards that may arise from faulty installations.

Incorporating inspections within the installation process fosters a culture of accountability and quality assurance among workers and contractors. Trained inspectors are equipped to evaluate various aspects of the work, including adherence to specified materials, alignment, and overall workmanship. This systematic approach ensures that every installation phase is scrutinised, reinforcing the importance of doing the job correctly from the outset. By prioritising inspections, stakeholders can safeguard their projects against the repercussions of non-compliance and uphold industry standards.

Training and Certification

Training and certification play a vital role in ensuring that professionals involved in pipe installation and repair possess the necessary skills and knowledge. This process not only enhances the technical competencies of workers but also reinforces their understanding of relevant regulations and best practices. A well-structured training programme can include both theoretical and practical components, ensuring that individuals are well-equipped to handle various challenges in the field.

Obtaining certification often requires individuals to meet specific educational and experiential criteria. This can involve completing recognised courses, passing examinations, and undertaking hands-on training. Ensuring that workers are appropriately trained and certified contributes to the overall quality of pipe installation and repair processes. Certifications also help to foster a culture of accountability and professionalism within the industry, ultimately benefitting both workers and the environment.

Qualifications Required for Compliance

Established qualifications are critical for ensuring compliance in the field of pipe installation and repair. Professionals typically require a combination of formal education and practical training. Vocational courses in plumbing and pipefitting provide essential knowledge related to materials, safety practices, and installation techniques. Certifications from recognised training organisations further validate expertise, indicating that individuals are well-versed in industry standards.

Ongoing professional development is equally important for maintaining compliance over time. Technological advancements and changes in regulations necessitate continuous education. Workshops and refresher courses enable professionals to stay updated, ensuring they understand the latest practices and legal requirements in pipe installation and repair. Adhering to these qualifications not only fosters a skilled workforce but also enhances overall safety and efficiency in the industry.

FAQS

What are the environmental impacts of non-compliant pipe installations?

Non-compliant pipe installations can lead to leaks and spills, which can contaminate soil and groundwater, disrupt local ecosystems, and contribute to pollution. These environmental damages can have long-term effects on wildlife and natural resources.

How does non-compliance affect the quality assurance processes in pipe installation?

Non-compliance undermines quality assurance processes by introducing risks that can lead to failures in the system. This can result in costly repairs, project delays, and diminished trust from clients and stakeholders.

What role do inspections play in ensuring compliance during pipe installation?

Inspections are crucial in identifying and rectifying non-compliance issues. They help ensure that installations meet regulatory standards and specifications, preventing potential hazards and ensuring the integrity of the piping systems.

What qualifications are required for professionals to ensure compliance in pipe installation?

Professionals should possess relevant training and certifications, such as a trade qualification in plumbing, pipeline engineering, or environmental management. Continuous education on regulations, standards, and best practices is also essential for maintaining compliance.

How can companies ensure their staff are properly trained for compliant pipe installations?

Companies can invest in regular training programs, workshops, and certification courses that focus on compliance regulations, installation techniques, and safety practices. Collaborating with accredited training providers can enhance the skill set of their workforce.