Table Of Contents

Reporting and Documentation Standards

Accurate reporting and documentation standards are essential in the field of pipe installation and repair within New South Wales. All activities must be meticulously logged to ensure compliance with local regulations. This includes recording the condition of existing pipes, materials used in repairs, and the methods applied during the installation or repair processes. Documentation should be clear and accessible, allowing for easy review by regulatory authorities. Maintaining these records not only supports accountability but also aids in addressing any future issues that may arise from repair activities.

Furthermore, the importance of adhering to strict documentation practices cannot be understated. Detailed records serve as both a guide for future maintenance and a legal safeguard for companies engaged in pipe installation and repair. Inconsistencies or lack of documentation can lead to significant repercussions, highlighting the need for thoroughness in every aspect of reporting. Compliance with these standards reinforces the integrity of repair work and upholds the safety and quality expectations set forth by governing bodies.

Required Records for Pipe Repair Activities

Maintaining precise records is essential in the realm of pipe installation and repair. Operators must document each stage of the repair process, detailing materials used, methods employed, and any challenges encountered. This documentation assists in ensuring compliance with existing regulations and serves as a reference for future inspections. Proper records facilitate accountability and provide insight into the effectiveness of repair techniques.

In addition to documenting the immediate repair activities, records should include any previous maintenance work carried out on the pipes. This historical data can be invaluable in assessing the long-term integrity of the pipe systems. Adhering to these record-keeping practices not only supports regulatory requirements but also contributes to the overall safety and reliability of pipe installation and repair operations.

Inspection and Compliance Checks

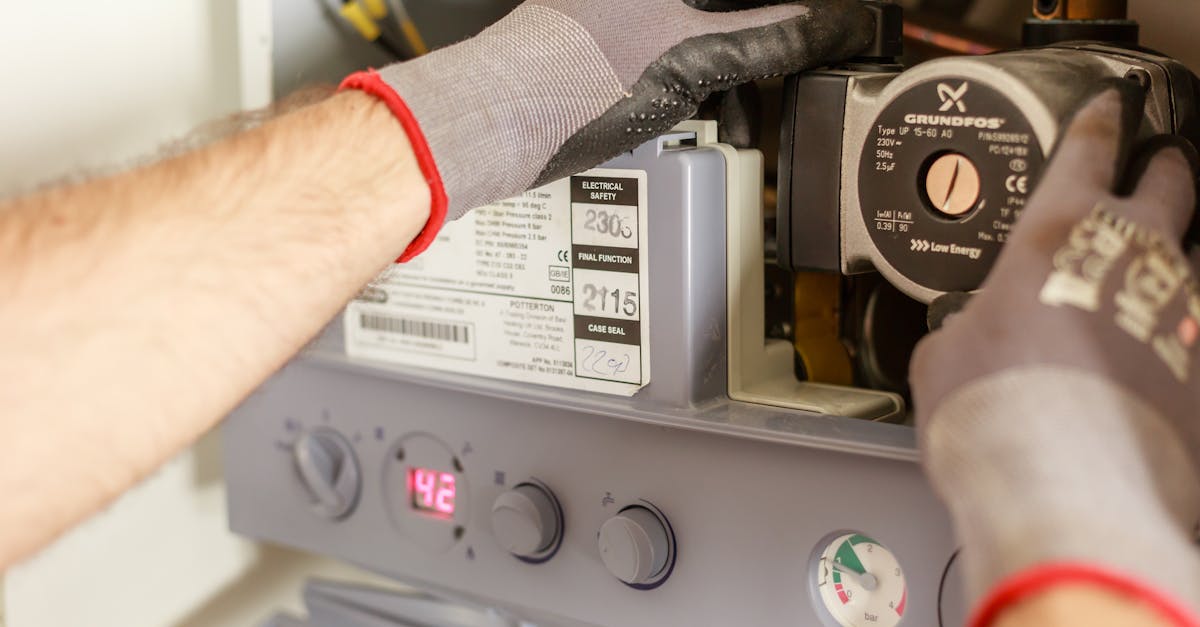

Inspection and compliance checks play a vital role in maintaining the integrity of pipe installation and repair activities. These checks ensure that all procedures adhere to the established regulations and standards. Qualified inspectors assess the installation methods, materials used, and overall workmanship to guarantee they meet the required specifications. Regular inspections help identify potential issues early, reducing the risk of future failures or environmental hazards.

The frequency of inspections is determined by the specific requirements set forth in the regulations. Typically, initial inspections occur during and after the installation phase. Follow-up checks may be scheduled at regular intervals, depending on the complexity of the project and previous compliance records. This systematic approach not only aids in adherence to safety and quality standards but also fosters a culture of accountability among those involved in pipe installation and repair.

Frequency and Process of Inspections

Inspections of pipe installation and repair activities in New South Wales are conducted at regular intervals to ensure compliance with established standards and regulations. The frequency of these inspections typically depends on the scope and scale of the project, with larger or more complex jobs requiring more frequent oversight. Regular inspections help identify potential issues early, ensuring that repairs adhere to safety and environmental protocols.

The inspection process involves a thorough evaluation of materials, workmanship, and compliance with approved plans. Qualified inspectors assess the site conditions and the integrity of existing infrastructure, providing feedback and recommendations as necessary. All findings are documented to maintain a clear record of compliance and to address any concerns that may arise during the course of pipe installation and repair.

Penalties for NonCompliance

Non-compliance with regulations governing pipe installation and repair in New South Wales can lead to significant penalties. These may include fines imposed on individuals or companies found guilty of violating safety standards or failing to complete necessary documentation. Authorities enforce these penalties to uphold public safety and environmental protections, ensuring that all pipe-related work meets the required guidelines.

Repeated violations can result in more severe consequences, such as the suspension or revocation of licenses that permit pipe installation and repair activities. This not only affects the offending party’s ability to operate but also raises concerns regarding the integrity of the surrounding infrastructure. Regulatory bodies are committed to maintaining high standards within the industry and will take appropriate action against those who jeopardise safety through non-compliance.

Consequences of Violating Regulations

Non-compliance with pipe repair regulations can lead to significant financial penalties for individuals and organisations involved in pipe installation and repair activities. The severity of ramifications often depends on the nature and extent of the violation. Regulatory bodies may impose fines that vary according to the infractions. In some cases, repeated offences may result in increased penalties, reflecting a zero-tolerance approach to contraventions of safety and environmental standards.

In addition to monetary fines, organisations may face reputational damage as a result of regulatory breaches. Public confidence in the ability of a company to manage pipe installation and repair safely can be severely undermined after an incident. This damage to reputation could lead to a loss of business opportunities and strained relationships with clients and local communities. Compliance with regulations is paramount for maintaining trust and ensuring long-term operational success in the industry.

FAQS

What are the key reporting and documentation standards for pipe repair activities in New South Wales?

The key reporting and documentation standards require operators to maintain comprehensive records of all repair activities, including details of the repairs performed, materials used, and any inspections conducted. These records must be available for review by regulatory authorities.

How often are inspections required for pipe repair activities in New South Wales?

Inspections are typically required to be conducted at least annually, though the frequency may vary based on the type of pipe and the specific regulations applicable to the area. Operators should consult local guidelines to ensure compliance.

What processes are involved in the inspection and compliance checks for pipe repairs?

The inspection process includes a thorough examination of repair work, review of documentation, and assessment of compliance with relevant standards and regulations. Inspectors may also conduct tests on the repaired pipelines to ensure their integrity and safety.

What are the penalties for failing to comply with pipe repair regulations in New South Wales?

Penalties for non-compliance can include fines, suspension of repair licenses, or even legal action, depending on the severity of the violation. In some cases, operators may also be required to undertake corrective actions at their own expense.

What are the consequences of violating pipe repair regulations?

Consequences of violating regulations can range from monetary fines and legal repercussions to the potential for increased scrutiny and oversight from regulatory bodies. Additionally, non-compliance can lead to safety hazards and damage to infrastructure, resulting in further liabilities.