Table Of Contents

Tightening Loose Connections

Loose connections can often be the culprit behind a leaky pipe, making it essential to address these issues promptly. Using the correct tools, such as a pipe wrench or an adjustable spanner, helps ensure secure fittings. It is important to apply even pressure while tightening to avoid causing further damage. Over-tightening can lead to deformation or cracking, so a careful approach is necessary when adjusting loose connections.

Pipe installation and repair requires attention to detail. Carefully check all fittings for signs of movement or wear. If you notice any play in the connections, loosening and re-tightening them may be sufficient to restore a proper seal. Always inspect your work periodically, especially in high-pressure areas, to ensure long-term stability and to prevent future leaks from developing.

How to Properly Tighten Pipe Fittings

When tightening pipe fittings, the primary goal is to achieve a secure connection without causing damage. Begin by ensuring that all surfaces are clean and free from debris. Use a wrench to tighten the fittings, applying steady pressure. It’s essential to avoid overtightening, as this can lead to both stripped threads and cracked fittings. Remember, the objective is to create a tight seal without compromising the integrity of the materials involved.

In the context of pipe installation and repair, attention to detail during this step is crucial. Different materials, such as metal and PVC, may require varying techniques. For metal fittings, a combination of hand-tightening followed by a wrench is often ideal, while PVC requires careful handling to avoid crushing. Always check for leaks after tightening, as this will help identify any areas that may need further adjustments or additional sealing methods.

Applying Plumbing Tape

Plumbing tape, commonly known as Teflon tape, is a handy tool for enhancing the seal on threaded pipe connections. It works by filling in the gaps and providing a barrier against leaks. For effective application, begin by cleaning the threads of the pipe to remove any debris or old tape. Take care to wrap the tape around the male threads in a clockwise direction, ensuring that it covers the threads evenly. This method will help create a tighter seal when the fittings are connected.

Proper use of plumbing tape plays a crucial role in pipe installation and repair. If applied correctly, it can prevent leaks and extend the life of your plumbing system. Avoid over-wrapping, as too much tape can interfere with the connection. A thin layer is often sufficient to create an effective seal. Always remember to check for compatibility with the specific type of pipes and fittings being used, as some materials may require different approaches.

Techniques for Effective Use of Teflon Tape

When using Teflon tape for pipe installation and repair, it's essential to wrap the tape around the pipe threads correctly. Start at the end of the pipe and wrap it in the direction of the thread spirals. This ensures that the tape doesn't unravel when the fitting is screwed on. Generally, two to three layers of tape are sufficient, as over-wrapping can lead to leaks or difficulty in tightening the connection. Ensure the tape is stretched slightly during application to help it conform to the threads.

After applying the Teflon tape, carefully screw the fittings together. Avoid using excessive force, as this can damage the threads. Make sure to check the tightness and inspect for any potential leaks after the installation is complete. If leaks persist after using Teflon tape, it may indicate that other issues are present in the pipe connection requiring further investigation or repair.

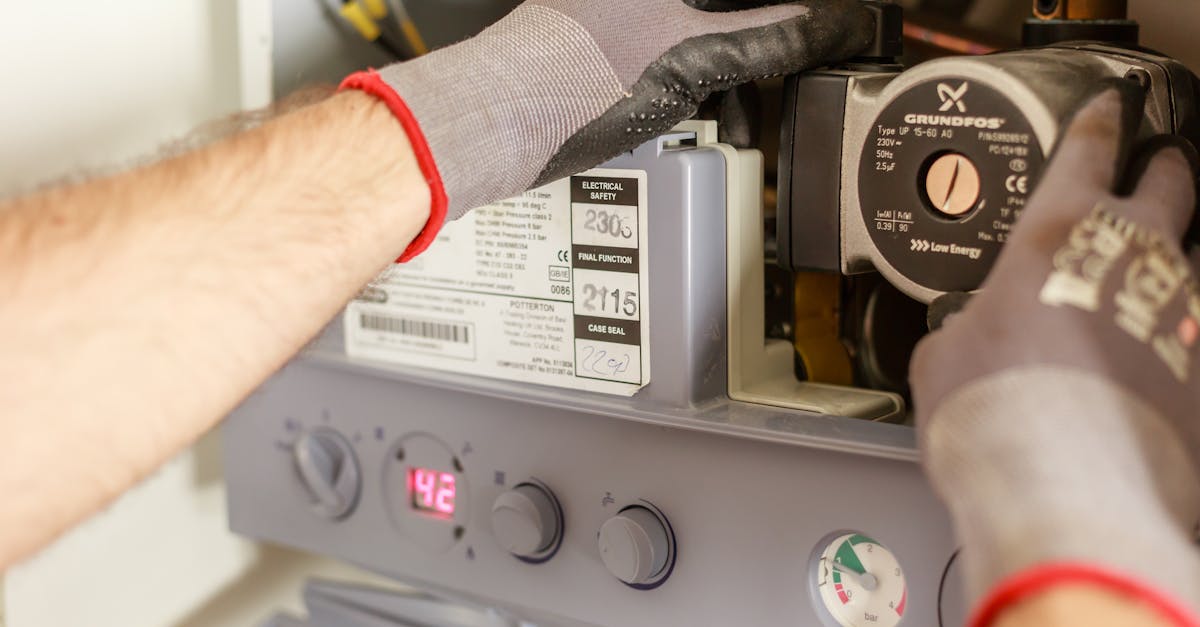

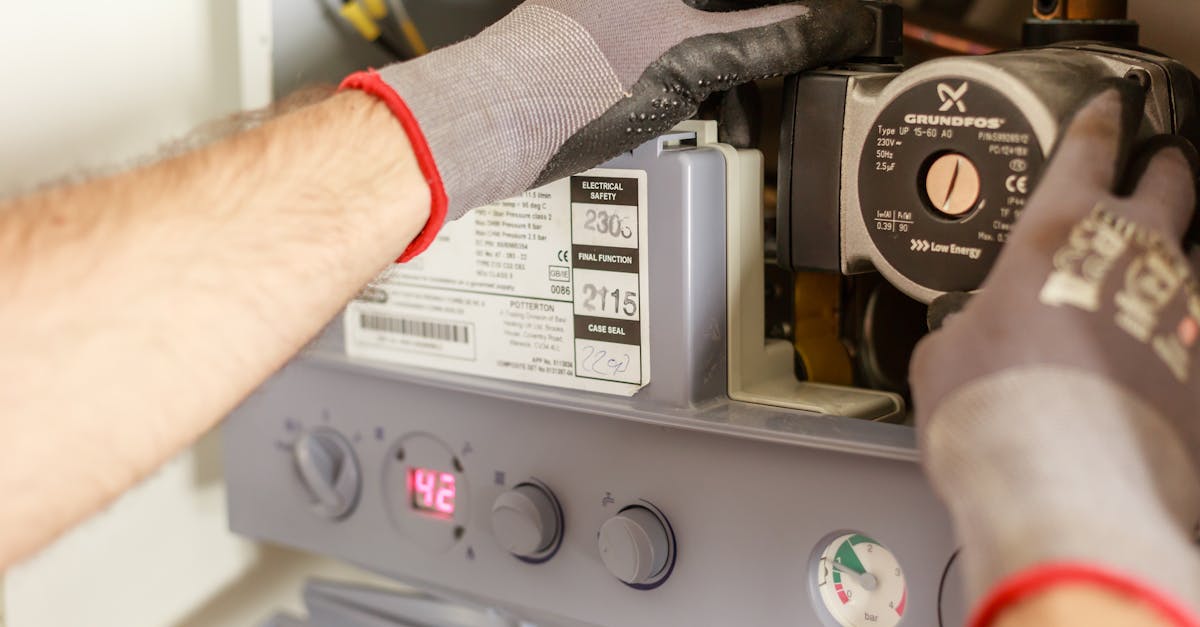

Replacing Damaged Components

When facing persistent leaks despite attempts to tighten connections or apply plumbing tape, it may be time to consider replacing damaged components. Inspect the entire pipe connection for visible cracks, rust, or deteriorated seals. A thorough examination helps to identify parts that no longer provide a watertight seal. Replacing these components ensures the integrity of the system and prevents further water damage.

Selecting the right materials is crucial for successful pipe installation and repair. Always opt for high-quality replacements that suit the specific type of piping in use, whether PVC, copper, or galvanised steel. Take care to measure accurately and use appropriate fittings to maintain a stable connection. By addressing damaged parts promptly, homeowners can avoid costly repair bills in the future and ensure their plumbing system operates efficiently.

When to Replace a Pipe Connection

Damage to a pipe connection can sometimes be beyond repair. Signs of corrosion, significant cracks, or widespread leaks often indicate that the pipe should be replaced rather than repaired. Additionally, if a connection fails repeatedly despite proper tightening and maintenance, it may be time to consider a replacement. Continuing to make repairs can lead to further complications, increasing the risk of water damage and resulting in higher costs down the line.

When assessing whether to replace a pipe connection, it’s crucial to evaluate the age and condition of the piping system. Older pipes, particularly those made from materials like galvanised steel or lead, may not hold up well over time. Regular inspections can help identify weak points before they become major issues. Investing in proper pipe installation and repair not only fixes immediate problems but also ensures the longevity of your plumbing infrastructure.

FAQS

What tools do I need to fix a leaky pipe connection?

To fix a leaky pipe connection, you typically need a wrench, plumber's tape (Teflon tape), a pipe cutter, and replacement parts if necessary.

How do I know if a pipe fitting is too loose?

You can tell if a pipe fitting is too loose if you notice water dripping from the connection or if you can easily turn the fitting by hand without resistance.

Is it safe to use Teflon tape on all types of pipes?

Teflon tape is generally safe to use on most threaded pipe connections, but it is not recommended for use on certain types of plastic pipes or where the tape could lead to over-tightening.

When should I consider replacing a pipe connection instead of repairing it?

You should consider replacing a pipe connection if it is severely corroded, cracked, or damaged beyond simple repairs, or if you are experiencing persistent leaks after tightening and using plumber’s tape.

Can I fix a leaky pipe connection without calling a plumber?

Yes, many leaky pipe connections can be fixed without a plumber by following proper techniques for tightening connections, applying plumber's tape, or replacing damaged components as needed.