Table Of Contents

Tools and Technologies Used

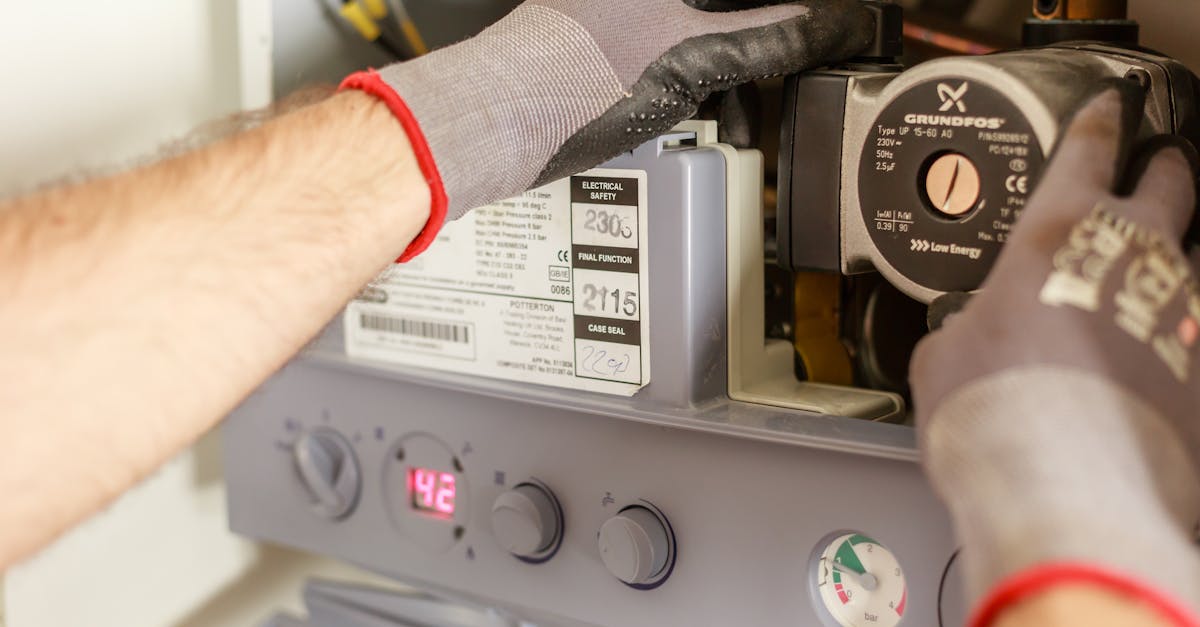

Engineers utilise a variety of tools and technologies to ensure compliance with pipe standards during installation and repair activities. Advanced software programs help in designing pipe systems that meet regulatory requirements. Also, 3D modelling technology enables visualisation of the entire piping layout, enhancing accuracy before installation begins. Inspection tools, such as ultrasonic and magnetic flux leakage devices, are crucial for assessing the integrity of existing pipes and identifying potential defects promptly.

In addition to software and inspection tools, data collection technologies play an essential role in monitoring compliance. Sensors integrated into pipe systems can continuously track pressure, flow rates, and potential leaks. This real-time data allows engineers to assess the performance of pipe installations and make informed decisions about maintenance or necessary upgrades. The incorporation of these innovative technologies facilitates proactive management of pipe installation and repair processes, promoting adherence to established standards.

Innovative Solutions to Monitor Compliance

Advancements in technology have introduced a variety of innovative solutions to monitor compliance in pipe installation and repair. Automated monitoring systems, equipped with sensors, can track key parameters such as pressure, temperature, and material integrity in real-time. These systems facilitate immediate detection of anomalies, allowing for prompt corrective actions. Drones equipped with high-resolution cameras and thermal imaging have emerged as valuable tools for inspecting pipe networks, particularly in hard-to-reach areas. These technologies not only enhance safety during inspections but also ensure adherence to the stringent standards required in the industry.

Another effective solution involves the use of cloud-based data management systems that consolidate information from various sources, allowing engineers to analyse compliance data efficiently. This centralised approach enables quick access to historical records and maintenance logs, which aids in identifying recurring issues and determining best practices for future projects. Integrating machine learning algorithms can further enhance predictive maintenance strategies, making it easier for engineers to forecast when repairs might be necessary. By utilising these cutting-edge solutions, the industry can uphold high standards in pipe installation and repair while minimising risks associated with non-compliance.

Case Studies of Compliance Success

Several case studies highlight successful compliance with pipe standards, demonstrating the vital role of engineers in various projects. One notable instance occurred in Queensland, where a large water utility company undertook a comprehensive inspection and upgrade of its pipeline infrastructure. Engineers implemented advanced technologies to assess the condition of existing pipes, ensuring compliance with industry standards. This proactive approach not only improved the longevity of the infrastructure but also reduced the likelihood of leaks and failures.

Another successful case study comes from a gas distribution network in New South Wales. Engineers adopted a systematic approach to pipe installation and repair, integrating rigorous compliance checks throughout the process. By utilising innovative monitoring techniques and regular training programs, the team achieved a significant reduction in non-compliance incidents. This project exemplified how adhering to standards could enhance safety and efficiency, ultimately benefiting both the company and its customers.

Lessons Learned from Effective Implementation

Effective implementation of compliance strategies highlights the importance of thorough training and consistent communication among team members. Engineers who understand the nuances of pipe installation and repair can significantly enhance the overall quality of work performed on-site. Establishing clear protocols helps ensure that all crew members are aware of the regulations that govern their tasks, facilitating smoother operations and reducing the likelihood of errors during projects.

Moreover, continuous evaluation of compliance practices contributes to long-term success. Regular audits and feedback sessions enable teams to identify areas for improvement and celebrate successes. Insights gained from past projects inform future strategies, creating a culture of accountability and proactive problem-solving. Engineers equipped with lessons from previous experiences are more adept at navigating the challenges associated with pipe installation and repair in accordance with evolving standards.

Training and Development for Engineers

Training and development in the field of pipe installation and repair is crucial for engineers to stay abreast of evolving standards and practices. Comprehensive training programs help ensure that engineers are well-versed in the technical specifications and compliance requirements set forth by relevant authorities. These educational initiatives often incorporate hands-on experience, allowing engineers to apply their knowledge directly to real-world scenarios. This practical exposure enhances their understanding and prepares them for the complexities of modern pipe systems.

Continuous professional development is essential for engineers to maintain their credentials and improve their skills. Workshops, seminars, and online courses provide valuable insights into the latest innovations and technologies in pipe installation and repair. Networking with industry leaders also fosters a culture of knowledge sharing, empowering engineers to implement best practices effectively. As compliance standards shift, ongoing training ensures engineers are equipped to address emerging challenges in the piping industry.

Building Expertise in Pipe Standards

Engineers must prioritise continuous education to build expertise in pipe standards. This involves staying updated on the latest regulations, techniques, and technologies in the field. Regular training sessions and workshops can greatly enhance an engineer's understanding of the specific requirements related to pipe installation and repair. Gaining insights from industry experts can provide practical knowledge that theoretical coursework may not cover.

In addition to formal training, hands-on experience plays a crucial role in developing expertise. Working closely with seasoned professionals during pipe installation and repair projects allows engineers to learn best practices and troubleshoot common issues. Collaboration with cross-functional teams also fosters a deeper understanding of how pipe standards impact various aspects of project delivery, from design to implementation. This multifaceted approach ensures that engineers are well-equipped to uphold the integrity of pipe systems.

FAQS

What are the primary responsibilities of engineers in ensuring compliance with pipe standards?

Engineers are responsible for designing, inspecting, and maintaining piping systems to ensure they meet established standards and regulations. This includes conducting risk assessments, implementing quality control measures, and staying updated on relevant laws and standards.

What tools and technologies are commonly used by engineers to monitor compliance with pipe standards?

Engineers utilise various tools and technologies such as digital inspection systems, pressure testing equipment, and compliance management software. These tools help in monitoring the integrity of piping systems and ensuring they adhere to safety and quality standards.

Can you provide examples of successful compliance in pipe standards from case studies?

Yes, several case studies illustrate successful compliance. For instance, a major oil and gas company improved its pipeline integrity management through advanced monitoring technologies, resulting in a significant reduction in leaks and maintenance costs. These case studies often highlight the importance of regular inspections and staff training.

What lessons can be learned from effective implementation of compliance measures?

Effective implementation teaches us the importance of proactive monitoring, regular training for staff, and continuous improvement of processes. Engaging stakeholders and fostering a culture of safety and compliance are also crucial for long-term success.

How can engineers build expertise in pipe standards?

Engineers can build expertise through ongoing education and training programs, attending industry conferences, and obtaining relevant certifications. Participating in workshops and collaborating with experienced professionals can also enhance their understanding of the latest standards and best practices.