Table Of Contents

Replacing a Damaged Section of Pipe

Replacing a damaged section of pipe requires careful assessment to identify the extent of the damage. The first step involves turning off the main water supply to prevent further leaking and flooding. Once the water is stopped, it is essential to drain the pipes by opening taps and allowing any remaining water to flow out. After ensuring that the area is dry, inspect the pipe for corrosion, cracks, or any other signs of deterioration. Mark the damaged section of the pipe and prepare for removal, ensuring to take necessary measurements for the new piece.

The next phase includes cutting the damaged section out using a pipe cutter or saw, making sure to have clean and straight edges for a proper fit later on. Pipe installation and repair require choosing the right type of replacement pipe, be it copper, plastic, or galvanised steel. Once the new piece is cut to the correct length, it can be joined using appropriate fittings and connectors. After securing everything in place, turn the water supply back on and check for leaks, confirming that the repair was successful before closing up any access points.

Tools Needed for Pipe Replacement

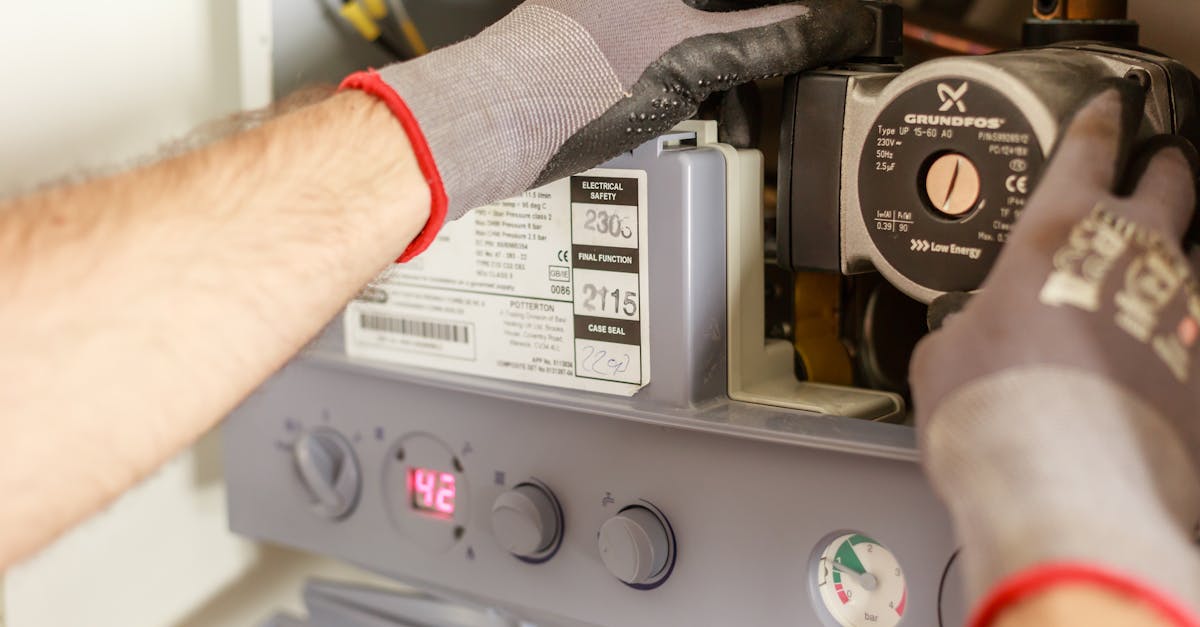

When embarking on a pipe replacement project, having the right tools at hand is essential for effective pipe installation and repair. A pipe cutter is necessary for making clean, precise cuts on the old pipe, ensuring a proper fit for the new section. Additionally, a set of wrenches will assist in loosening and tightening fittings. A measuring tape ensures accurate sizing, while pipe clamps help secure the pipes during the installation process.

Safety gear is also a crucial part of the toolkit. Wearing gloves protects hands from sharp edges and hazardous materials. Safety goggles prevent eye injuries from debris or splashes. An adjustable pliers set can be helpful for gripping irregular surfaces or fittings. By preparing with these tools and safety equipment, the process of pipe installation and repair becomes smoother and more efficient.

Preventative Measures to Avoid Future Leaks

Preventative measures can significantly reduce the risk of future leaks in your plumbing system. Regular inspection of pipes is essential. Look for visible signs of wear, such as corrosion or stress points. An annual check-up by a licensed plumber ensures that any potential issues are identified early. Keeping the area around the pipes clean and free from debris can also help, as foreign objects may cause unintentional damage.

Proper pipe installation and repair play a crucial role in preventing leaks. Using the correct materials suited to your specific water supply is vital. Avoid the temptation to use mismatched fittings or substandard materials, as this can lead to weaknesses. Additionally, ensuring that all joints are sealed securely will help maintain a robust plumbing system. Regular maintenance practices, including clearing drains of any build-up, will also contribute to the longevity of your pipes.

Maintaining Your Plumbing System

Regular maintenance of your plumbing system is crucial for preventing leaks and ensuring the longevity of your pipes. Inspecting visible pipes for signs of wear, rust, or leaking connections can help you catch issues before they escalate. Additionally, checking for water stains on ceilings and walls may indicate hidden leaks. Investing time in these preventative measures allows you to address small problems promptly, saving significant repair costs in the long run.

Pipe installation and repair should always be performed by qualified professionals. Proper installation techniques reduce the risk of leaks caused by incorrect fittings. Regular servicing can also highlight potential corrosion spots or weaknesses in the system. This proactive approach not only enhances the efficiency of your plumbing but also contributes to a safer, more comfortable living environment.

Understanding Pipe Corrosion

Pipe corrosion is a significant concern for many homeowners. The process occurs when metal pipes react with water, air, and surrounding materials, leading to deterioration over time. Factors such as water quality, temperature, and the presence of chemicals can accelerate corrosion. Understanding these influences is essential for maintaining the integrity of your plumbing system. Regular inspections can help identify early signs of wear, which is crucial to prevent serious leaks or pipe failure.

For effective pipe installation and repair, expertise in materials and environmental conditions is vital. Selecting the right type of pipe can minimise corrosion risks. For instance, copper and PVC pipes are generally more resistant compared to older iron or steel options. Homeowners should also consider the water pH and levels of dissolved minerals during installation. This knowledge can significantly enhance the lifespan of the plumbing system while reducing potential repair costs in the long run.

Factors Contributing to Pipe Deterioration

Several factors can accelerate pipe deterioration, compromising the integrity of plumbing systems. Age plays a crucial role; older pipes made from materials like copper or galvanised steel are more susceptible to rust and corrosion. Environmental factors such as soil type and moisture levels also influence the rate of deterioration. Chemical reactions between water and pipe materials can lead to the build-up of scale or deposits that may weaken pipes over time.

Improper pipe installation and repair can exacerbate these issues, leading to premature failure. For instance, inadequate sealing at joints can allow air and moisture to enter the system, promoting corrosion. Additionally, water pressure that exceeds the pipe's capacity may cause stress, leading to cracks and leaks. Regular inspections and maintenance can mitigate these risks, ensuring a longer lifespan for plumbing installations.

FAQS

What are some common signs of a leaking pipe?

Common signs of a leaking pipe include water stains on walls or ceilings, increased water bills, dampness in the area, and the sound of running water even when taps are off.

How can I temporarily stop a pipe leak until I can make a permanent repair?

You can temporarily stop a pipe leak by using a plumber's tape, a rubber patch secured with a hose clamp, or wrapping the area with a cloth to absorb the water. However, these are just short-term solutions.

When should I consider replacing a section of my pipe?

You should consider replacing a section of your pipe if it is severely damaged, corroded, or if leaks persist despite repairs. It’s often more cost-effective in the long run to replace damaged pipes.

What tools do I need for replacing a section of a leaking pipe?

The tools needed for replacing a section of a leaking pipe typically include a pipe cutter, adjustable wrench, plumber's tape, and possibly soldering equipment, depending on the type of pipe you are working with.

How can I prevent future leaks in my plumbing system?

To prevent future leaks, regularly inspect your plumbing system, insulate pipes to prevent freezing, avoid harsh chemicals in drains, and schedule routine maintenance checks with a professional plumber.