Table Of Contents

Material Selection for Trenchless Techniques

The choice of materials for trenchless pipe installation and repair is crucial for ensuring longevity and performance. Materials must be suitable for the specific environmental conditions and the intended use of the pipes. Factors such as soil type, groundwater conditions, and the presence of corrosive substances should heavily influence the selection process. Popular materials include polyvinyl chloride (PVC), high-density polyethylene (HDPE), and ductile iron, each offering distinct advantages for different applications.

Ultimately, selecting the right material not only impacts the performance of the installation but also affects future maintenance and operational efficiency. The durability and resistance to external factors ensure that systems remain functional over extended periods. Engineers must consider factors such as weight, flexibility, and joint integrity during the decision-making process. Each choice plays a vital role in the overall success of pipe installation and repair strategies.

Common Materials Utilised

A variety of materials are commonly utilised in trenchless pipe installation and repair, each catering to specific project requirements and environmental conditions. PVC (polyvinyl chloride) pipes have gained popularity due to their lightweight nature, corrosion resistance, and ease of handling. Additionally, HDPE (high-density polyethylene) pipes are favoured for their flexibility and ability to withstand high pressure, making them suitable for various applications, including water and gas distribution. The choice of material can significantly influence the long-term performance and durability of the installed pipe.

Steel pipes remain a reliable option, particularly for applications involving heavy loads or high-temperature fluids. Their robustness ensures lasting integrity under challenging conditions. Another material that is gaining traction is ductile iron, known for its repairability and resistance to impact. Each material presents distinct advantages, necessitating a thoughtful selection process to align with the specific needs of trenchless pipe installation and repair projects.

Environmental Considerations

Environmental considerations are crucial in the implementation of trenchless pipe installation techniques. These methods are generally preferred for their ability to minimise surface disruption. However, it is essential to assess the potential impacts on local ecosystems and wildlife. Careful planning and site assessments can help identify sensitive areas that may be affected during the installation process.

Mitigating environmental impacts during pipe installation and repair is vital to maintaining biodiversity. Techniques such as using biodegradable lubricants and selecting appropriate installation routes can significantly reduce the ecological footprint. Adopting such strategies not only fosters compliance with environmental regulations but also reinforces the industry's commitment to sustainability.

Minimising Impact During Installation

Effective trenchless pipe installation techniques aim to minimise environmental impact while ensuring efficient operations. By utilising methods such as horizontal directional drilling and pipe bursting, disturbances to the surrounding landscape and existing infrastructure can be significantly reduced. These techniques allow for the replacement or installation of pipes without the need for extensive excavation, preserving vegetation and minimising soil disruption.

Mitigating potential damage to ecosystems during pipe installation and repair is crucial. Proper planning and assessment of the site can identify sensitive areas that require special attention. Employing advanced equipment and techniques further contributes to a more sustainable approach, lessening the risk of waterway contamination and promoting overall ecological health. Operators must remain vigilant, adhering to environmental guidelines throughout the process to safeguard local habitats.

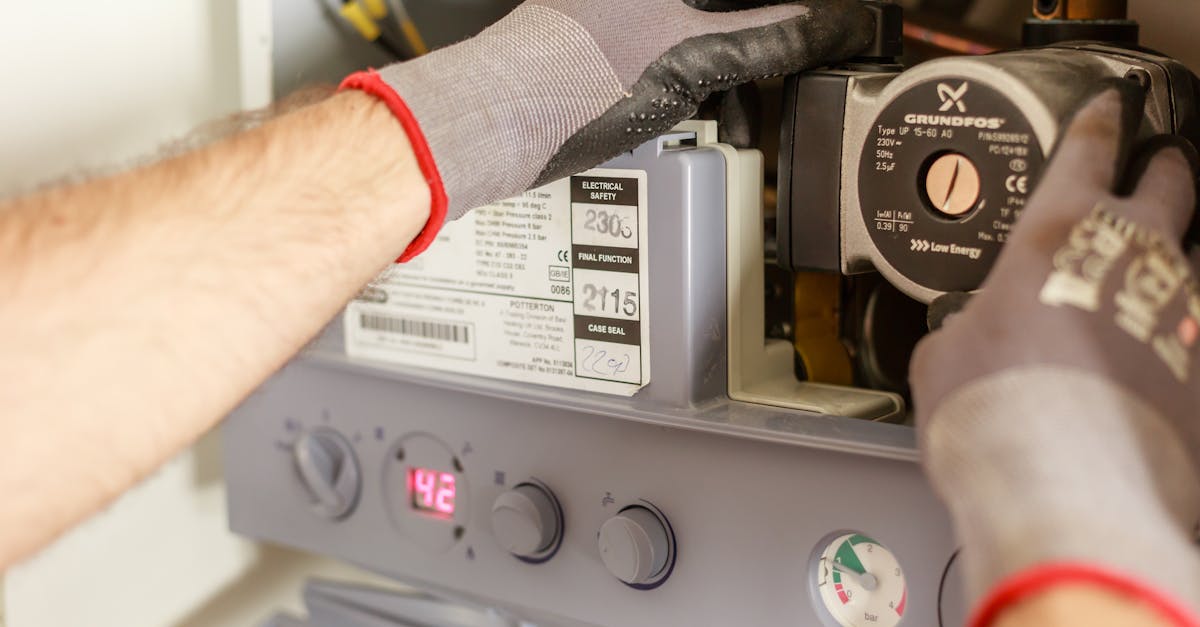

Safety Protocols in Trenchless Operations

Safety protocols must be strictly adhered to during trenchless operations to ensure the well-being of workers and the integrity of the project. Proper training and certification in safe operation practices are essential. Workers should be equipped with personal protective equipment (PPE) such as helmets, gloves, and safety goggles to mitigate the risks associated with the construction environment. Regular inspections of equipment, coupled with maintenance checks, play a crucial role in preventing accidents and malfunctions.

Pipe installation and repair using trenchless methods necessitates careful planning to address potential hazards effectively. Risk assessments should be conducted prior to the commencement of work, identifying any environmental factors and ensuring compliance with local regulations. Communication among team members is vital to address any issues promptly and ensure that everyone is aware of their responsibilities. Emergency response procedures must also be established beforehand to provide a swift reaction in case of any incidents.

Best Practices for Worker Safety

Implementing best practices for worker safety during trenchless pipe installation and repair is crucial for minimizing risks. Workers should undergo thorough training that covers the specific hazards associated with trenchless techniques. Regular safety drills can ensure that all team members are familiar with emergency protocols, equipment handling, and proper personal protective equipment (PPE) usage. This proactive approach not only promotes a culture of safety but also empowers workers to identify potential dangers in their environment.

Furthermore, maintaining clear communication among team members is essential. Establishing designated roles helps streamline operations and ensures that everyone understands their responsibilities. Regular site inspections should be conducted to assess any hazards, particularly in areas where machinery and human activity intersect. Safety briefings at the start of each shift reinforce awareness of any immediate issues related to pipe installation and repair, helping to cultivate vigilance and accountability among workers on-site.

FAQS

What are trenchless pipe installation techniques?

Trenchless pipe installation techniques are methods used to install underground pipes without the need for extensive excavation. These methods minimise surface disruption and are often quicker and more cost-effective than traditional trenching.

What materials are commonly used in trenchless pipe installation?

Common materials utilised in trenchless techniques include high-density polyethylene (HDPE), polyvinyl chloride (PVC), and ductile iron. Each material has its own benefits depending on the specific application and environmental conditions.

How can environmental impact be minimised during trenchless installation?

Environmental impact can be minimised by using techniques that reduce soil disturbance, implementing erosion control measures, and carefully planning the installation route to avoid sensitive ecosystems.

What safety protocols should be followed during trenchless operations?

Safety protocols in trenchless operations include conducting thorough risk assessments, ensuring proper training for workers, using appropriate personal protective equipment (PPE), and adhering to local safety regulations and standards.

Are trenchless installation techniques suitable for all types of projects?

While trenchless techniques are versatile and can be applied to various projects, their suitability depends on factors such as soil conditions, pipe material, project size, and environmental considerations. It’s essential to evaluate these factors before deciding on the installation method.