Table Of Contents

Compliance with Local Regulations

Adhering to local regulations is a crucial aspect of pipe installation and repair, especially in flood-prone areas. Each region may have specific guidelines regarding materials, depth, and positioning that aim to minimise potential damage during flood events. Familiarising oneself with these regulations ensures that installations are not only compliant but also enhance the resilience of infrastructure against environmental challenges.

Local authorities often provide detailed building codes and standards that technicians must follow. These documents outline the required safety measures and recommended practices for effective pipe installation and repair. Ignoring these regulations could lead to significant issues, including increased vulnerability to flooding and potential penalties for non-compliance. It is essential for contractors and property owners alike to prioritise understanding and implementing these regulations during the installation process.

Navigating Building Codes and Standards

Understanding the local building codes and standards is crucial for ensuring proper pipe installation and repair in flood-prone areas. These regulations dictate the materials, techniques, and safety measures that must be adhered to, minimising the risk of damage from flooding. Compliance with these codes not only protects properties but also enhances safety for residents. It is vital to consult with local authorities or a qualified professional to clarify specific requirements in the area, as these can vary significantly, especially in regions prone to flooding.

Incorporating the latest building codes into every aspect of pipe installation and repair allows for improved resilience against environmental challenges. Builders and contractors should keep abreast of any updates or amendments to regulations that may impact their work. Proper documentation and adherence to standards facilitate smoother inspections and approvals, ultimately ensuring that the installation is robust against potential flood risks. Engaging experienced professionals who are familiar with local regulations can also help navigate these complex requirements effectively.

Installation Techniques for FloodProne Areas

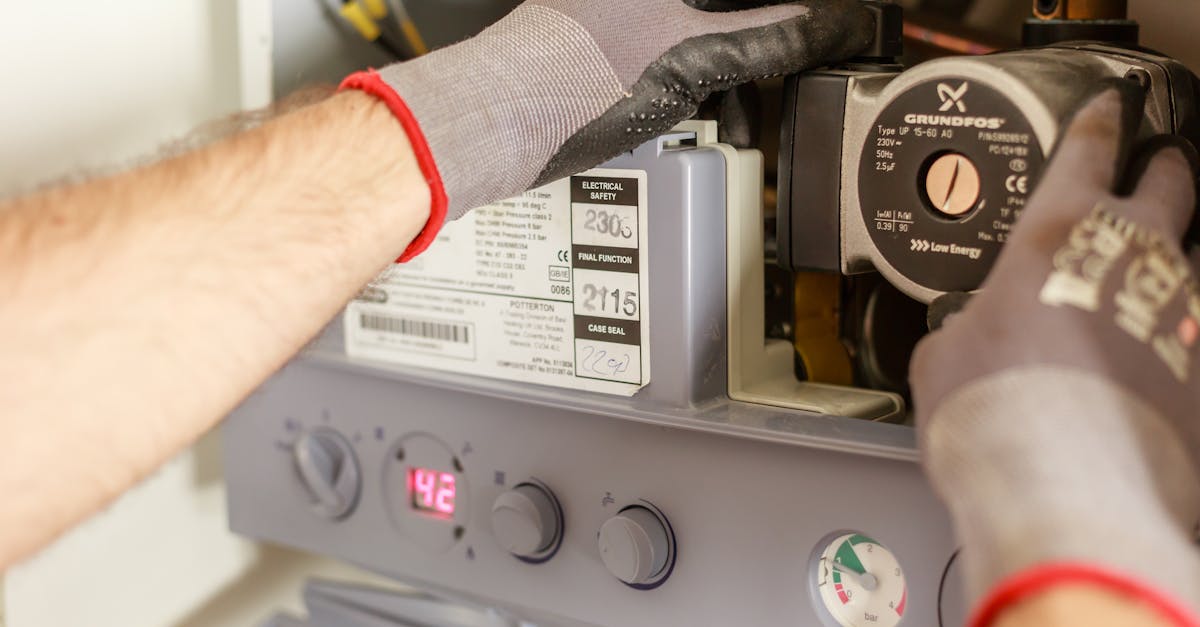

When undertaking pipe installation and repair in flood-prone areas, it is crucial to assess the specific site conditions thoroughly before proceeding with any plan. The selection of appropriate materials plays a significant role in enhancing the resilience of the system. Opt for high-grade, corrosion-resistant pipes capable of withstanding submerged conditions. Additionally, utilising flexible joints can accommodate soil shifts and movement, which is common during flooding events.

It is also essential to adopt techniques that elevate the pipeline above potential flood levels. Installing pipes at a higher grade ensures that they remain operational during adverse weather conditions. Implementing proper drainage around the installation site can mitigate water accumulation, further protecting the integrity of the pipes. Engaging experienced contractors familiar with local environmental challenges can enhance the effectiveness of the techniques employed, ensuring compliance with necessary guidelines.

Best Practices for Secure Pipe Placement

Secure placement of pipes in flood-prone areas demands careful consideration and strategic planning. It is essential to ensure that pipes are elevated above potential flood levels, which can significantly reduce the risk of water ingress and subsequent damage. Selecting materials that can withstand corrosion and impact from debris is also crucial. Additionally, using protective casings can provide an extra layer of security, safeguarding pipes from shifting soil or erosion caused by flooding.

When conducting pipe installation and repair, incorporating anchor systems can further stabilise the pipes and prevent movement during flooding events. Approved techniques such as trenching deeply and backfilling appropriately ensure proper support for the installed pipes. Regular assessments of the surrounding environment are necessary to adapt to changing conditions and maintain the integrity of the pipe systems over time. By following these best practices, the longevity and effectiveness of the installation can be greatly enhanced.

Maintenance Strategies PostInstallation

Implementing a robust maintenance strategy post-installation is crucial for ensuring the durability and functionality of piping systems in flood-prone areas. Regular inspections should focus on identifying any signs of wear, corrosion, or potential blockages caused by debris accumulation. Special attention must be given to joints and connections, as these are often the most susceptible to damage during extreme weather events. A comprehensive maintenance schedule should be established, including routine checks and the immediate addressing of detected issues. This proactive approach can significantly extend the lifespan of the installed systems.

Pipe installation and repair not only requires adherence to best practices during the initial phase but also demands ongoing vigilance. Keeping detailed records of maintenance activities aids in tracking the condition of the pipes over time. Engaging qualified professionals for periodic evaluations ensures that any required repairs are performed promptly, thus preventing more extensive damage. By prioritising maintenance and inspections, systems can better withstand the challenges presented by flooding, ultimately safeguarding property and resources.

Regular Checks and Repairs to Prevent Failure

Regular inspections play a crucial role in ensuring the integrity of pipe installation and repair in flood-prone areas. These checks should focus on identifying signs of wear, corrosion, and potential blockages that could affect water flow. It is advisable to establish a maintenance schedule that adheres to local regulations while considering changes in weather patterns that may impact flood risks. Maintaining accurate records of all inspections and repairs will help track the condition of the pipes over time.

In addition to regular checks, timely repairs are essential to mitigate risks associated with flooding. Any identified issues should be addressed immediately to prevent more significant problems down the line. This proactive approach not only extends the life of the pipes but also ensures that they function optimally during adverse weather conditions. Engaging qualified professionals for repair work provides confidence that the standards required for pipe installation and repair are met, reducing the likelihood of future failures.

FAQS

Why is it important to comply with local regulations when installing pipes in flood-prone areas?

Compliance with local regulations ensures that installations meet safety standards and are designed to withstand potential flooding, reducing the risk of damage and liability.

What are some common building codes and standards relevant to pipe installation in flood-prone areas?

Common building codes may include those set by the Australian Building Codes Board (ABCB) and local council regulations that focus on flood resilience and environmental safety.

What installation techniques are recommended for pipes in flood-prone areas?

Recommended techniques include elevating pipes above expected flood levels, using flexible joints to accommodate movement, and ensuring proper drainage to prevent water accumulation.

What are best practices for secure pipe placement in flood-prone areas?

Best practices include anchoring pipes securely, using corrosion-resistant materials, and ensuring that all joints are watertight to prevent leaks during flooding.

What maintenance strategies should be implemented post-installation to prevent pipe failure?

Regular maintenance strategies include conducting inspections for signs of wear or corrosion, clearing debris from drainage systems, and repairing any leaks or damages promptly.