Table Of Contents

Environmental Considerations

Environmental considerations play a crucial role in the planning and execution of pipe installation and repair. The ecological impact of such activities can be significant, affecting soil stability, local waterways, and biodiversity. It is essential to conduct thorough environmental assessments before commencing work to identify sensitive areas and implement measures that mitigate potential damage. Practising responsible techniques helps ensure that ecosystems remain intact while services are installed or repaired.

Adopting sustainable practices during pipe installation and repair reduces the carbon footprint associated with these projects. Relevant guidelines should be followed to manage waste materials, ensuring that they are disposed of properly or recycled where possible. Implementing erosion control measures and maintaining good site hygiene are vital steps in protecting the surrounding environment. By prioritising these considerations, the industry can contribute to a more sustainable future while meeting infrastructure needs.

Minimising Impact During Installation

Minimising impact during the installation of pipes is crucial for both the environment and the surrounding community. Proper planning is essential before commencing any work. Assessing the site for potential hazards and sensitive areas can help identify risks that may arise during pipe installation and repair. Choosing appropriate construction methods and machinery reduces disturbance to local wildlife and vegetation. Implementing measures such as using noise barriers and scheduling work during times that will minimise disruption can make a significant difference.

Another important aspect to consider is the management of soil and water resources on-site. Erosion control methods, such as silt fences or sediment traps, should be employed to prevent sediment runoff into nearby water bodies. Additionally, it is vital to ensure that any excavation and backfilling processes are carefully managed to maintain soil integrity and reduce compaction. By prioritising these strategies, the impact of pipe installation and repair on the environment can be significantly reduced, ensuring a more sustainable approach to infrastructure development.

Quality Control and Assurance

Quality control and assurance are crucial components of pipe installation and repair processes. Adhering to strict guidelines ensures that all materials and procedures meet the required standards. This includes regularly assessing the quality of pipes prior to installation, as well as monitoring the workmanship throughout the process. Compliance with industry benchmarks not only enhances the durability of the installation but also mitigates the risk of future failures.

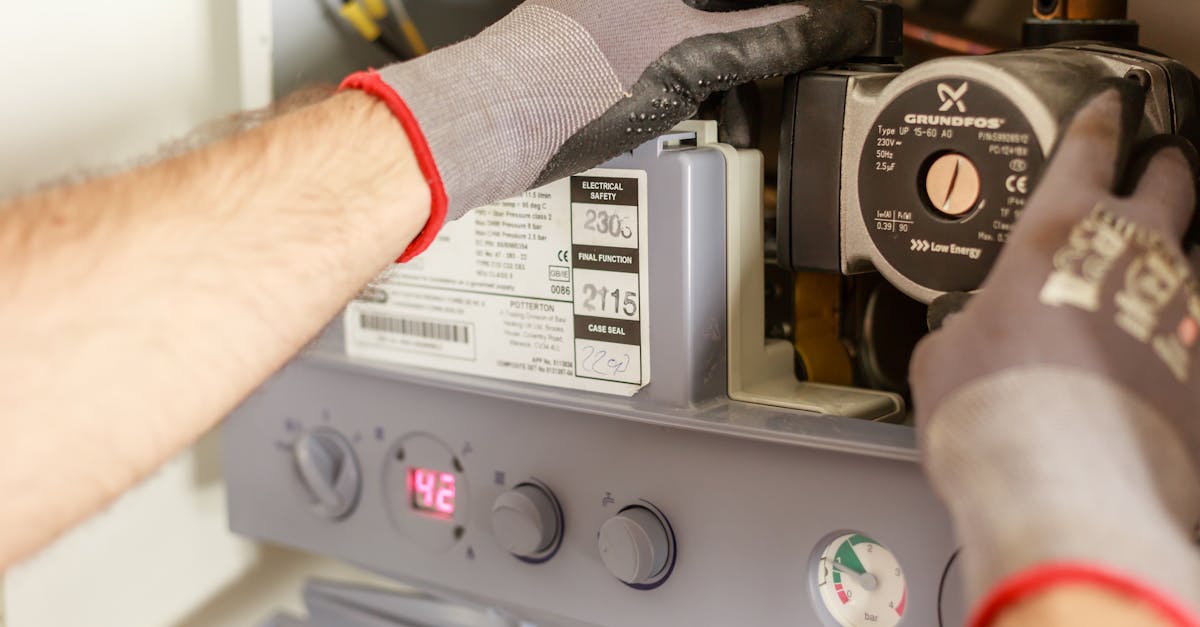

Inspection and testing protocols play a significant role in maintaining high-quality standards. Various methods such as visual inspections, non-destructive testing, and pressure testing are employed to confirm the integrity and functionality of the pipes installed. These practices help identify potential issues early on, ensuring that corrective actions can be implemented promptly. Ultimately, effective quality control and assurance foster confidence in the reliability and longevity of pipe installations and repairs.

Inspection and Testing Protocols

Inspection and testing protocols are essential to ensure the integrity and reliability of pipe installation and repair. Regular inspections should be conducted at key stages, including post-installation and during maintenance checks. This enables the early detection of any potential issues such as leaks, structural weaknesses, or material defects. All inspections must be documented comprehensively, providing a clear record of the condition of the pipes throughout their lifespan.

Testing methods should align with industry standards to assess the performance and safety of installed pipes. Pressure testing is commonly employed to verify the strength of the piping system. Additionally, non-destructive testing techniques can be utilised to evaluate the quality of materials without causing any damage. Adhering strictly to these protocols not only enhances the durability of pipe installations but also promotes environmental safety and regulatory compliance within New South Wales.

Maintenance Guidelines for Installed Pipes

Proper maintenance of installed pipes is essential to ensure their longevity and reliable performance. Regular inspections should be conducted to identify any signs of wear, corrosion, or leakage. Keeping accurate records of these inspections helps in tracking the condition over time. Prompt attention to minor issues can prevent more significant problems later. Establishing a routine for cleaning and maintaining the pipes is also recommended. This could involve flushing pipes to remove debris and sediment buildup, which can impact flow efficiency.

In addition to inspections, evaluating the surrounding environment is crucial. External factors such as soil conditions, vegetation, and nearby constructions can affect the integrity of installed pipes. Pipe installation and repair must consider these aspects during their lifecycle. Engaging qualified professionals for maintenance tasks enhances the reliability of the systems. Moreover, aligning maintenance schedules with seasonal changes can further optimise the durability and functionality of the infrastructure.

Recommended Maintenance Schedule

A recommended maintenance schedule is essential for ensuring the longevity and functionality of installed pipes. Regular inspections should occur at least annually, focusing on any visible signs of wear or damage. Addressing minor issues promptly can prevent more significant problems later. Assessing factors such as soil movement and environmental changes will aid in identifying potential threats to pipe integrity, making timely intervention crucial.

Additionally, pipe installation and repair efforts should incorporate routine checks for leaks, corrosion, and blockages. Scheduled cleaning and flushing of the systems can enhance performance while providing insights into any underlying issues. Keeping meticulous records of all maintenance activities will facilitate effective monitoring and help streamline future repairs or upgrades, ensuring that the entire pipeline system remains in optimal condition.

FAQS

What is the Code of Practice for Pipe Installation in New South Wales?

The Code of Practice for Pipe Installation in New South Wales provides guidelines and standards to ensure safe, efficient, and environmentally responsible practices during the installation and maintenance of pipes.

Why are environmental considerations important in pipe installation?

Environmental considerations are vital to minimise the impact on natural surroundings, protect local ecosystems, and comply with regulatory requirements, ensuring sustainable practices during pipe installation.

What should be included in the quality control and assurance process?

The quality control and assurance process should include inspection and testing protocols, documentation of procedures, adherence to standards, and ongoing monitoring to ensure the integrity and performance of installed pipes.

How often should maintenance be carried out on installed pipes?

The recommended maintenance schedule typically includes regular inspections and servicing at predetermined intervals, which may vary based on the type of pipe, its usage, and environmental conditions.

What are the key components of an effective maintenance plan for pipes?

An effective maintenance plan should include routine inspections, testing for leaks or blockages, cleaning schedules, as well as documentation of maintenance activities and any necessary repairs or adjustments.