Table Of Contents

Safety Precautions for Workers

Ensuring the safety of workers during pipe installation and repair is paramount. Proper training is essential for all personnel involved in these tasks. Workers should be familiar with the specific hazards associated with the job, including exposure to hazardous materials and the risks of working with heavy machinery. It is important for workers to follow established safety protocols and maintain a clean working environment. Identifying potential risks before commencing work can help in implementing necessary precautions and safeguards.

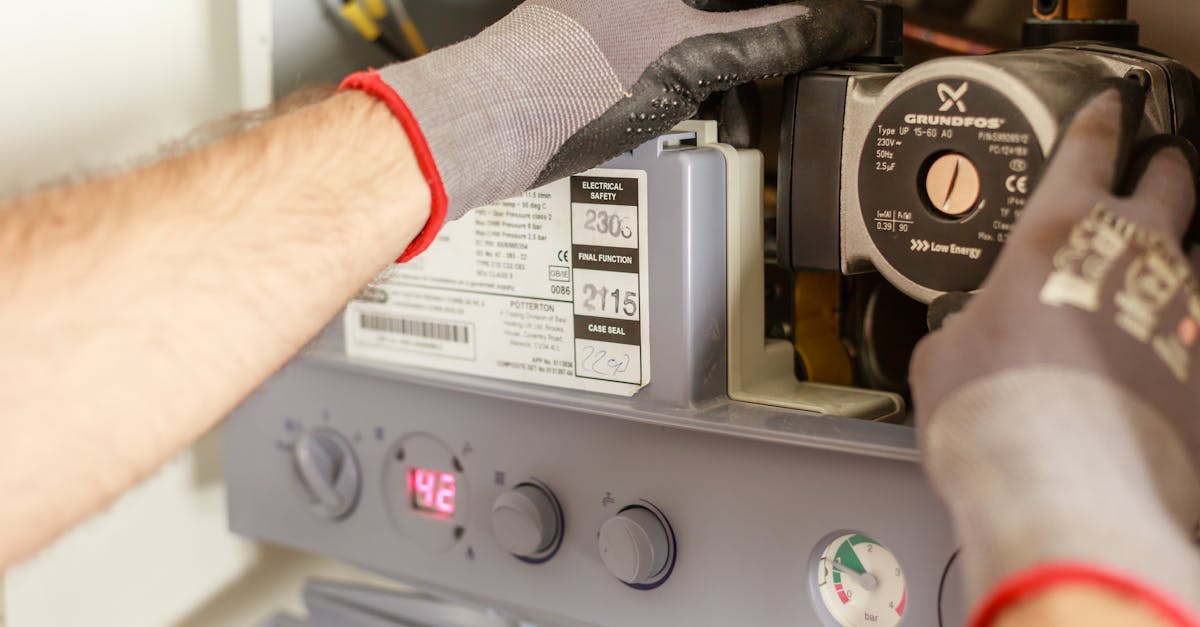

In addition to training, the proper use of protective equipment is critical in enhancing worker safety. This includes hard hats, gloves, and eye protection to prevent injury from falling debris or exposure to chemicals. Safety procedures should be regularly reviewed and updated to incorporate feedback from workers who have experienced pipe installation and repair first-hand. Regular safety drills can help reinforce the importance of preparedness in the event of an emergency situation.

Personal Protective Equipment (PPE) Guidelines

Personal protective equipment (PPE) is essential for ensuring the safety of workers involved in pipe installation and repair. Proper gear must be selected based on the specific risks associated with the task. This includes wearing helmets to protect against head injuries, gloves to prevent cuts and abrasions, and safety goggles or face shields to shield against flying debris. Additionally, high-visibility clothing should be worn to ensure workers remain visible, especially in busy or low-light conditions.

Foot protection is also critical, with sturdy, slip-resistant boots providing essential support and safety from heavy equipment or materials. Respirators or masks may be necessary in environments where exposure to hazardous substances is possible, ensuring workers are not inhaling harmful particles. Implementing these PPE guidelines not only complies with safety regulations but significantly reduces the likelihood of injury during pipe installation and repair. Regular training and reinforcement of PPE protocols help maintain awareness and understanding among all personnel involved.

Reporting and Documentation

Timely reporting and thorough documentation are crucial following any pipe failure incident. All workers involved must be aware of the procedures for reporting failures, as this promotes transparency and accountability. Accurate records facilitate effective communication and help identify recurring issues. After a pipe installation and repair, documenting the specific circumstances surrounding a failure provides valuable insights for future prevention strategies.

Incident reports must include details such as the time of the occurrence, the personnel involved, and any immediate actions taken in response to the failure. Such records should be archived systematically, ensuring easy access for future reference. Regular audits of these documentation practices reinforce compliance with industry regulations and help improve safety measures. Proper reporting serves not just as a legal requirement but also enhances the overall integrity of the pipe installation and repair processes.

Required Records and Incident Reports

Accurate and timely documentation is crucial following a pipe failure incident. Required records typically include detailed incident reports, which should outline the events leading up to the failure, the immediate response actions taken, and any measures implemented to mitigate damage. This documentation not only supports regulatory compliance but also aids in analysing the effectiveness of the emergency procedures in place. Ensuring that all personnel involved in the incident contribute to the report will provide a comprehensive overview of the circumstances and responses during the emergency.

In addition to incident reports, records of pipe installation and repair activities are essential for maintaining a clear history of the pipe systems in use. This documentation may include maintenance logs, inspection reports, and any previous failure records. Such information plays a vital role in identifying potential risks associated with specific materials or installation methods. By thoroughly documenting these aspects, organisations can enhance their understanding of equipment reliability and improve future planning for pipe maintenance and emergency protocols.

Review and Evaluation of Emergency Procedures

The review and evaluation of emergency procedures are crucial for ensuring the effectiveness of response strategies related to pipe failures. Regular assessments help identify weaknesses in existing protocols and provide opportunities for updates based on new regulations or technological advancements. Training sessions and simulations assess worker preparedness and allow for feedback from those directly involved in pipe installation and repair.

Incorporating lessons learned from past incidents into the evaluation process leads to more robust emergency plans. It is important to involve relevant stakeholders, including safety officers and maintenance teams, in discussions following an incident. Gathering insights on the practical application of emergency procedures ensures that measures remain relevant and effective. This collaborative approach fosters a culture of continuous improvement and enhances safety standards within the industry.

Conducting PostIncident Analysis

Conducting a post-incident analysis is a critical step in understanding the causes and effects of pipe failures. This process involves gathering all relevant data from the incident, including photographs, witness accounts, and any available measurements taken during the event. By meticulously documenting the circumstances surrounding the failure, teams can identify patterns or recurring issues that may have led to the incident. This information is vital for improving future practices and ensuring that similar failures can be avoided.

In the context of pipe installation and repair, an effective post-incident analysis serves as a foundation for training and protocol refinement. Lessons learned from past incidents can inform the development of more robust safety measures and enhance workers' awareness of potential hazards. Additionally, engaging all stakeholders in this process ensures comprehensive insights and promotes a culture of continuous improvement within the organisation. Regular reviews of these analyses contribute to better preparedness and a heightened commitment to safety standards in the field.

FAQS

What should I do first if I suspect a pipe failure?

The first step is to ensure your safety and the safety of others by evacuating the area if necessary. Then, report the incident to your supervisor or emergency contact immediately.

What type of Personal Protective Equipment (PPE) is recommended during a pipe failure emergency?

Recommended PPE may include hard hats, safety goggles, gloves, and protective clothing. Specific requirements may vary depending on the type of materials involved in the pipe failure.

How do I document a pipe failure incident?

Documentation should include details such as the date and time of the incident, location, nature of the failure, actions taken, and any injuries or damages sustained. Ensure you complete any required incident report forms.

What is the importance of conducting a post-incident analysis?

Conducting a post-incident analysis is crucial for identifying the root causes of the failure, evaluating the effectiveness of the emergency response, and implementing improvements to prevent future incidents.

Are there specific regulations that govern emergency procedures for pipe failures?

Yes, various regulations exist that require compliance with safety standards and emergency response protocols. It's important to be familiar with local and national regulations relevant to your industry.