Table Of Contents

Impact of Noncompliance

Non-compliance with material certification standards can have severe repercussions in pipe installation and repair. The use of materials that do not meet regulatory specifications can lead to failures in the pipeline systems. These failures could result in significant financial losses due to repairs and replacements. Moreover, non-compliance can attract hefty fines and legal liabilities, creating additional burdens for companies involved in such operations.

Beyond regulatory aspects, the implications of using non-certified materials extend to public safety and environmental integrity. Inadequate materials may deteriorate faster, leading to leaks and potential contamination of local ecosystems. The risks rise sharply in areas where pipelines transport hazardous substances; accidents could harm not only the environment but also communities. Ensuring compliance through certification is therefore essential for protecting both human health and the environment during pipe installation and repair activities.

Risks of Using Noncertified Materials

Using non-certified materials in pipe installation and repair can lead to significant structural failures. These materials may not meet the necessary strength and durability standards, resulting in leaks or bursts. Such failures pose serious threats to infrastructure, potentially leading to costly repairs and disruptions. Additionally, the long-term performance of the installed systems can be compromised, leading to recurring issues that affect overall efficiency.

Another critical risk associated with non-certified materials is the potential for safety hazards. When pipes fail, the resulting leaks can create unsafe environments, particularly if hazardous substances are involved. This not only endangers the workers involved in the installation and repair process but also places the surrounding communities at risk. Environmental contamination from leaking pipes can have far-reaching effects, making the use of certified materials essential for safeguarding both human health and the ecosystem.

Best Practices for Material Certification

To ensure the integrity of pipe installation and repair, it is crucial to establish a rigorous material certification process. This involves verifying the compliance of materials with relevant industry standards and regulations. Thorough documentation should accompany each batch of materials, demonstrating their quality and suitability for the intended application. Regular audits of suppliers can help maintain these compliance standards and prevent any lapses in quality.

Another best practice involves engaging with reputable suppliers that have established track records in material certification. Building strong relationships with these suppliers promotes better communication regarding product specifications and any potential changes. Additionally, investing time in training the workforce about the importance of using certified materials can enhance overall safety and efficiency in both pipe installation and repair projects. This not only reduces the risk of using subpar materials but also fosters a culture of quality and responsibility within the team.

Ensuring Your Suppliers are Certified

Ensuring that your suppliers are certified is a crucial step in the process of pipe installation and repair. Certified suppliers adhere to established standards, which can significantly reduce the risk of using substandard materials. Thoroughly vetting your suppliers is essential. This may involve checking their certifications, reviewing their quality control processes, and understanding their compliance with industry regulations. A reliable supplier not only contributes to the integrity of your project but also fosters trust in the materials being used.

Furthermore, maintaining a relationship with certified suppliers ensures that you receive consistent quality and performance in your pipe installation and repair projects. Regular audits and inspections can help verify that suppliers maintain their certification standards. Establishing clear communication channels with suppliers allows for timely updates on any changes to certification statuses. Ultimately, choosing certified suppliers lays the foundation for successful and safe pipe installations.

Material Certification and Safety

Material certification plays a crucial role in ensuring the safety of pipe installation and repair projects. Only certified materials guarantee compliance with industry standards, which helps to prevent failures that could lead to catastrophic events. When unverified materials are used, the structural integrity of pipes can be compromised, raising concerns about leaks, pressure failures, and other dangerous incidents. Inadequate material quality can also pose significant risks to the surrounding environment and community.

The implications of using non-certified materials extend beyond technical failures and can affect worker safety directly. Poorly manufactured pipes may lead to hazardous working conditions, increasing the likelihood of accidents during installation or maintenance. Furthermore, the potential for environmental damage can result in costly remediation processes and long-term ecological harm. Material certification, therefore, acts as a safeguard for both workers and the environment in the context of pipe installation and repair practices.

Protecting Workers and the Environment

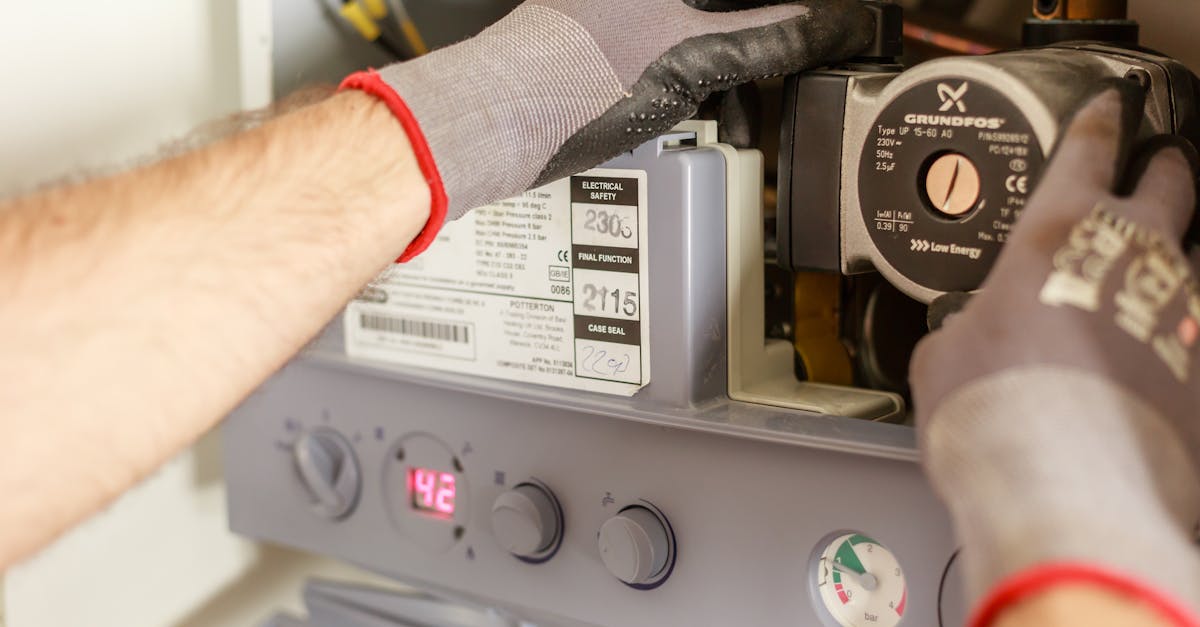

Material certification plays a crucial role in ensuring the safety of workers involved in pipe installation and repair. When certified materials are used, the risk of failure during the installation process significantly decreases. This reliability translates into a safer working environment, minimising the potential for accidents or injuries that can arise from using substandard or non-compliant materials. Properly certified pipes are tested for durability and performance under various conditions, providing peace of mind to those responsible for the installation.

The environmental aspect of certified materials cannot be overlooked. Using non-certified materials in pipe installation and repair can lead to leaks or failures that compromise ecosystems and water supplies. Certified materials undergo stringent testing to ensure they meet established environmental standards, thereby reducing the likelihood of harmful substances being released into the environment. This responsible approach contributes to sustainable practices and protects both workers and the surrounding environment from potential hazards.

FAQS

What is material certification, and why is it important in pipe installation?

Material certification is a documented assurance that materials meet specific standards and regulations. It is crucial in pipe installation to ensure safety, reliability, and compliance with industry standards, mitigating risks associated with non-certified materials.

What are the risks associated with using non-certified materials in pipe installation?

Using non-certified materials can lead to structural failures, leaks, environmental hazards, and increased maintenance costs. It also poses safety risks to workers and the surrounding community, making compliance essential.

How can I ensure that my suppliers are certified?

You can ensure your suppliers are certified by requesting their certification documents, checking their compliance with relevant industry standards, and verifying their credentials through industry associations or regulatory bodies.

What best practices can be followed for material certification in pipe installation?

Best practices include conducting regular audits of suppliers, maintaining thorough documentation of all materials, ensuring proper training for staff on certification processes, and keeping updated with changes in industry standards.

How does material certification contribute to worker and environmental safety?

Material certification ensures that the materials used are tested and verified for safety and durability, reducing the likelihood of accidents and failures. This, in turn, protects workers from hazards and minimises the environmental impact of potential leaks or spills.