Table Of Contents

Identifying Common Pipe Installation Errors

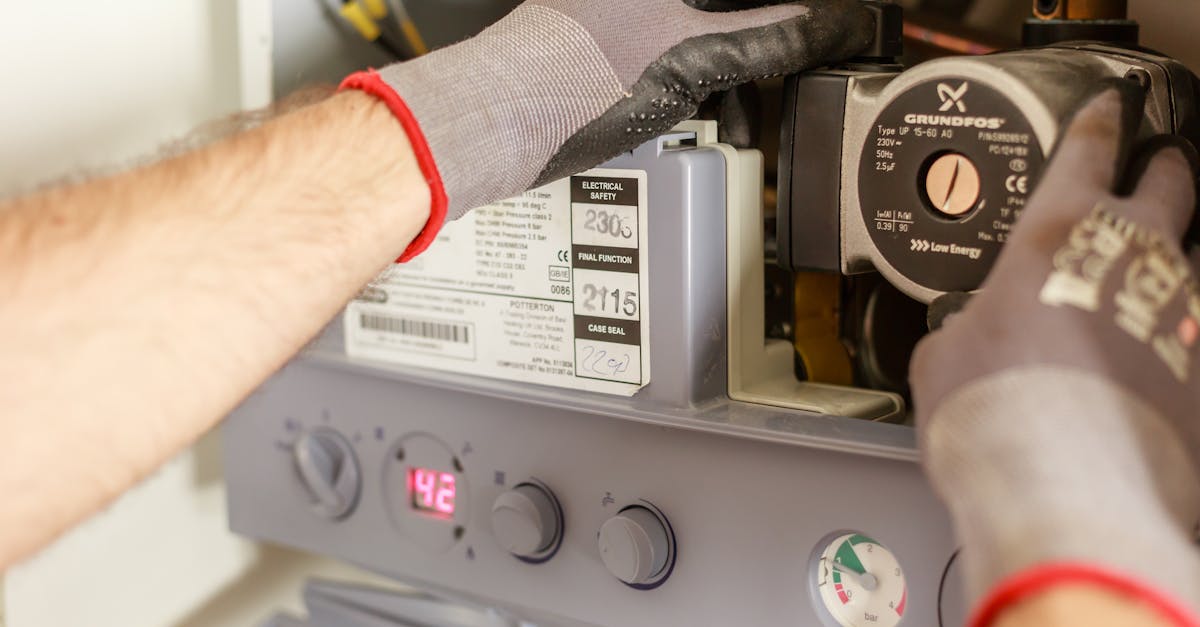

Pipe installation and repair can often be plagued by various errors that compromise the integrity and functionality of the entire system. One common mistake is improper alignment of pipes, which can lead to significant leaks and pressure issues. Another frequent error involves inadequate preparation of the pipe surfaces during installation. Failing to clean or bevel the edges can result in poor sealing or joint formation, ultimately affecting the performance of the plumbing system.

Additionally, the selection of appropriate materials plays a crucial role in successful pipe installation and repair. Using the wrong type of pipe for a specific application can lead to deterioration or failure under extreme conditions. Moreover, overlooking the environmental factors, such as soil type and temperature fluctuations, may also result in unforeseen complications. Identifying these errors early on is critical to preventing costly repairs and ensuring a long-lasting plumbing system.

Techniques for Early Detection and Correction

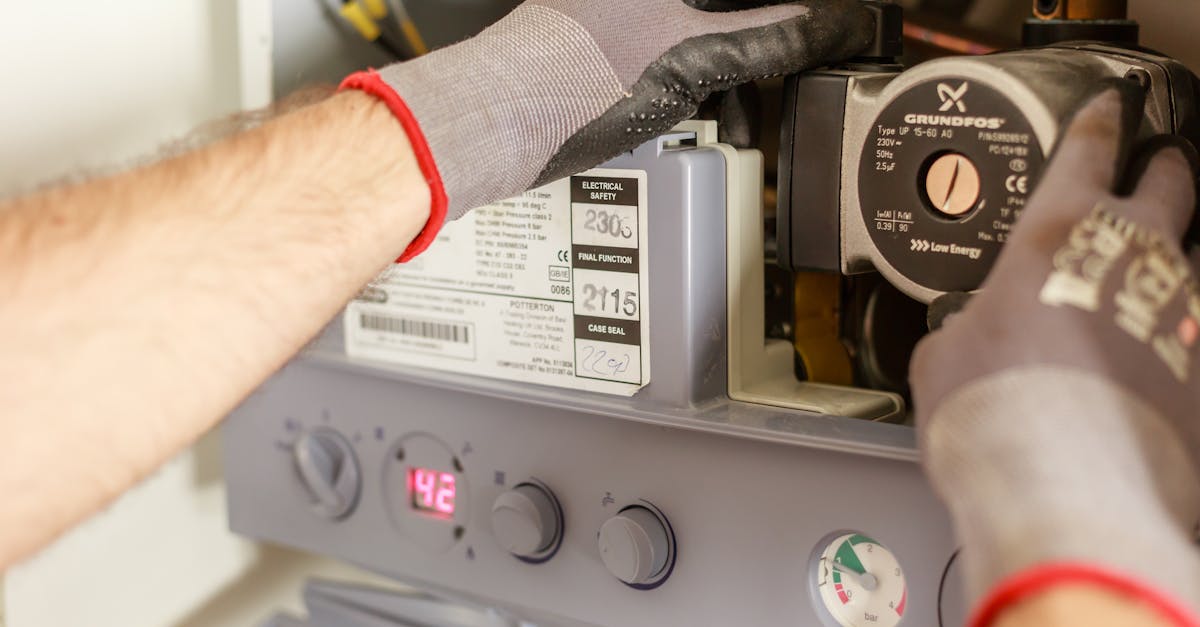

Timely detection of errors during pipe installation and repair can significantly minimise issues in the future. Utilising advanced imaging technology, such as infrared cameras or ultrasonic sensors, enables teams to identify leaks and structural weaknesses before they become critical. Regular inspections during different phases of installation can also help pinpoint deviations from established standards. These techniques facilitate quick corrective actions, reducing the risk of costly repairs later.

In addition to technology, effective communication among team members plays a crucial role in early detection. Encouraging a culture where workers can report concerns or inconsistencies without hesitation helps ensure that potential issues are addressed immediately. Implementing checklists tailored for pipe installation and repair can serve as a guide for teams, promoting consistent quality and enabling swift corrections when necessary. This proactive approach not only enhances the integrity of installations but also reinforces the importance of thoroughness in every project.

Importance of Training and Certification

Training and certification play a critical role in ensuring that professionals in the field are well-equipped with the knowledge and skills necessary for successful outcomes. Pipe installation and repair require not only a solid understanding of materials and techniques but also a comprehensive grasp of safety and compliance standards. By prioritising training, companies can cultivate a workforce that is adept at identifying potential problems early and executing installations that meet or exceed industry benchmarks.

Moreover, certified professionals are often more trusted by clients due to the rigour of the training programmes they have completed. This trust translates into customer satisfaction, as well-trained individuals are less likely to commit errors during pipe installation and repair. Furthermore, certification provides a level of assurance that the installation staff understand the importance of adhering to best practices, ultimately reinforcing the value of quality control processes in the industry.

Ensuring Competence Among Installation Staff

Ensuring the competence of installation staff is vital for the success of any project involving pipe installation and repair. Adequately trained professionals possess both the technical skills and the problem-solving abilities necessary to navigate the complexities of pipe systems. Regular training sessions help to keep staff updated on the latest techniques, safety procedures, and industry standards. Continuous education reinforces best practices, allowing skilled tradespeople to maintain high-quality work despite evolving technologies and methodologies.

Certification programs further bolster the capabilities of installation teams. These certifications not only verify the skills of individual workers but also demonstrate the commitment of the company to uphold quality standards. Companies that prioritize training and certification are better positioned to deliver reliable pipe installation and repair services. They establish a culture of excellence that translates into greater customer trust and satisfaction, ensuring that projects are completed efficiently and effectively.

Customer Satisfaction and Quality Control

Quality control plays a crucial role in fostering customer satisfaction during pipe installation and repair. When companies implement rigorous quality control measures, they ensure that installations meet industry standards and customer expectations. This commitment to quality not only reduces the likelihood of future issues but also instils confidence in customers. A well-executed installation means fewer callbacks and repairs, leading to enhanced trust in the service provider.

Customers appreciate transparency and reliability in service delivery. Quality control processes contribute to building a reputation for dependability, as clients can rely on the integrity of the work performed. Additionally, effective communication about the quality control measures in place reassures customers that their project is being handled with utmost care. In the long run, excellent quality control in pipe installation and repair translates into stronger customer relationships and increased business referrals.

Building Trust through Reliable Installations

Reliable installations form the backbone of customer satisfaction in any construction project, especially in pipe installation and repair. When clients know they can depend on the integrity and durability of the pipes installed, their confidence in the service provider increases. Regular quality control measures ensure that each installation not only meets industry standards but also aligns with the specific needs of the client.

Trust is cultivated through consistent performance and transparency in the installation process. Clients who experience seamless communication and diligent work are more likely to return for future projects and recommend services to others. By prioritising quality control in every aspect of pipe installation and repair, service providers establish a reputation that highlights their commitment to excellence and customer care.

FAQS

What are some common errors in pipe installation?

Common errors in pipe installation include misalignment, inadequate sealing, improper support, and the use of substandard materials. These issues can lead to leaks, structural failures, and costly repairs.

How can we detect installation errors early?

Techniques for early detection include regular inspections, using technology such as cameras or pressure tests, and implementing a systematic checklist during the installation process to ensure all steps are followed correctly.

Why is training and certification important for pipe installation?

Training and certification ensure that installation staff are knowledgeable about industry standards, best practices, and safety regulations, which significantly reduces the risk of errors and enhances the overall quality of the installation.

How can we ensure competence among installation staff?

Competence can be ensured through ongoing education and training, hands-on experience, and regular evaluations. Encouraging staff to obtain relevant certifications also helps maintain a high standard of quality.

How does quality control impact customer satisfaction?

Quality control directly impacts customer satisfaction by ensuring that installations are reliable, safe, and function as intended. This builds trust with clients and can lead to repeat business and positive referrals.