Table Of Contents

Technological Innovations in Pipe Installation

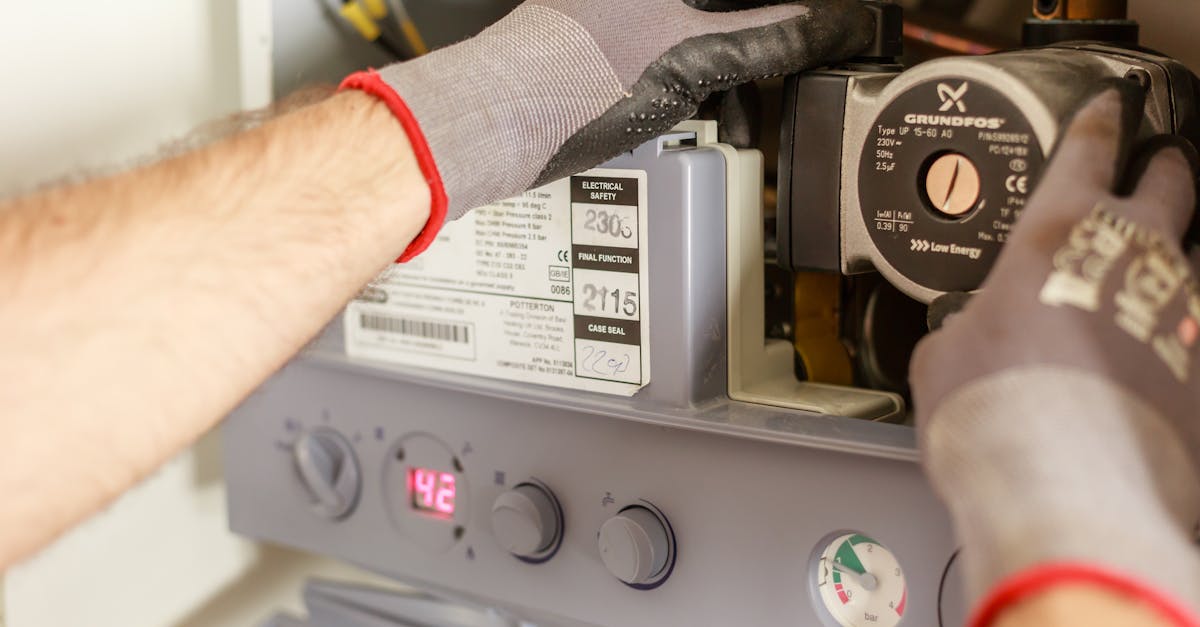

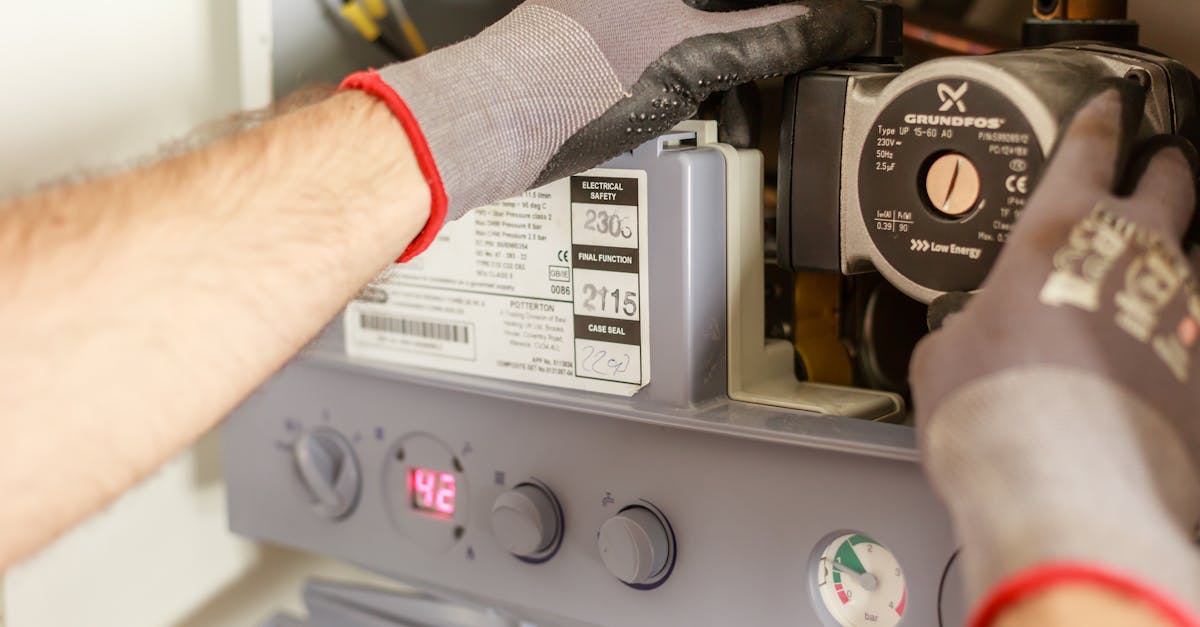

In recent years, technological advancements have significantly transformed the landscape of pipe installation and repair. Innovations such as trenchless technology have reduced the need for extensive excavation, leading to less disruption in urban areas. This method allows for the installation of new pipes through established pathways, minimising environmental impact. Additionally, enhanced materials like high-density polyethylene (HDPE) offer improved durability and resistance to corrosion, extending the lifecycle of pipes while reducing maintenance needs.

The introduction of advanced monitoring systems is revolutionising how pipe conditions are assessed and managed. Smart sensors and IoT-enabled devices can remotely monitor pipeline integrity, providing real-time data on potential leaks or weaknesses. This proactive approach not only enhances the efficiency of pipe installation and repair processes but also supports broader environmental objectives by reducing waste and resource consumption. As these technologies continue to evolve, they promise even greater improvements in both operational efficiency and environmental sustainability.

Advancements Supporting Environmental Goals

Recent advancements in materials technology have transformed pipe installation and repair, offering new options that significantly reduce environmental impact. For instance, the development of trenchless technologies has allowed for the installation of pipelines with minimal disruption to the surrounding ecosystem. These methods not only conserve soil and vegetation but also prevent potential contamination from conventional excavation techniques. Additionally, the emergence of bio-based and recycled materials increases the sustainability of pipeline projects, reducing reliance on virgin resources.

Furthermore, innovations in monitoring and maintenance systems enhance the efficiency of existing pipelines, helping to prevent leaks and failures that could lead to environmental damage. Smart sensors integrated into pipe systems provide real-time data on pressure and flow, enabling proactive repairs before issues escalate. By adopting these advanced technologies, the industry moves closer to aligning with environmental goals, ensuring that pipe installation and repair processes contribute to more sustainable practices in resource management.

Compliance Challenges in Environmental Policy

The regulatory landscape surrounding environmental policies often presents significant compliance challenges for companies involved in pipe installation and repair. These challenges arise from the complex interplay between national legislation and local regulations. Navigating these requirements can be burdensome as organisations strive to meet both environmental objectives and operational necessities. A lack of standardisation in policies can lead to confusion, making it difficult to implement consistent practices across different jurisdictions.

In addition to regulatory discrepancies, companies must also contend with the enforcement of compliance measures. Frequent inspections and audits can disrupt ongoing projects, impacting timelines and budgets. Pipe installation and repair companies face the dual responsibility of adhering to these policies while maintaining efficiency in their operations. This balancing act can result in increased costs and resource allocation challenges, as businesses aim to remain compliant without jeopardising productivity.

Navigating Regulatory Requirements

Navigating the complex landscape of regulatory requirements in relation to pipe installation and repair can be daunting for industry professionals. Several layers of regulations exist, with both federal and state bodies imposing specific standards aimed at protecting the environment. Understanding these regulations is crucial for companies to ensure compliance while effectively managing operational costs. The dichotomy between stringent environmental policies and the practical aspects of installation often leads to confusion about what is permissible and what is not.

Within this framework, organisations must remain vigilant regarding updates to legislation that can impact their practices. Regular audits and assessments of current processes can aid in identifying areas for improvement and compliance gaps. Engaging with regulatory authorities and industry bodies provides further insight into best practices and emerging trends. By fostering strong relationships and maintaining open lines of communication, companies can better navigate the regulatory environment surrounding pipe installation and repair, ensuring they meet both legal and environmental obligations.

Case Studies of Successful Integration

Several organisations have successfully integrated environmental policies into their pipe installation and repair processes. One notable case involved a utility company that adopted trenchless technology to reduce soil disturbance and minimise disruption to local ecosystems. By utilising horizontal directional drilling, the company significantly lowered its carbon footprint during installation. The approach not only resulted in effective pipe placement but also demonstrated a commitment to preserving the surrounding environment, leading to positive community feedback and support.

Another example highlights a major urban infrastructure project where pipe installation and repair adhered to strict environmental standards. The project team implemented the use of biodegradable drilling fluids and ensured that all materials used were sourced sustainably. This integration of eco-friendly practices not only met regulatory compliance but also set a benchmark for future projects in the region. Stakeholders noted improved relationships with environmental groups and increased community trust, showcasing the potential benefits of aligning environmental initiatives with construction practices.

Lessons Learned from Best Practices

Implementing best practices in pipe installation and repair has proven essential for enhancing environmental outcomes. For instance, using trenchless technology minimises soil disruption and the potential for habitat loss. Techniques such as horizontal directional drilling lead to more efficient installations, reducing the carbon footprint associated with traditional methods. Successful projects often feature comprehensive training for workers, ensuring that they are equipped to follow innovative practices that also comply with environmental standards.

The analysis of case studies reveals that engaging stakeholders early in the planning process fosters smoother operations and compliance with environmental policies. Projects that prioritise community input are more likely to anticipate potential pitfalls and adapt strategies accordingly. Also, utilising real-time monitoring systems during pipe installation and repair provides valuable data that helps maintain adherence to environmental regulations. These lessons underscore the importance of integrating technology and community involvement to achieve not only efficient installations but also sustainable environmental practices.

FAQS

What role do technological innovations play in pipe installation?

Technological innovations enhance the efficiency and effectiveness of pipe installation processes, allowing for improved accuracy, reduced waste, and overall better compliance with environmental standards.

How do advancements in pipe installation support environmental goals?

Advancements such as the use of eco-friendly materials, trenchless technology, and smart monitoring systems help minimise environmental impact by reducing land disruption, conserving resources, and lowering emissions during installation.

What are some common compliance challenges in environmental policy related to pipe installation?

Compliance challenges often include navigating complex regulations, aligning with varying local and national standards, and ensuring that all stakeholders are adequately informed and trained to meet these requirements.

How can organisations effectively navigate regulatory requirements in pipe installation?

Organisations can effectively navigate regulatory requirements by staying updated on legislation, engaging with regulatory bodies, conducting regular training for staff, and implementing best practices for compliance throughout the installation process.

What are key lessons learned from successful case studies in integrating environmental policy with pipe installation standards?

Key lessons include the importance of collaboration among stakeholders, the value of investing in innovative technologies, and the necessity of ongoing monitoring and evaluation to ensure that both installation practices and environmental goals are being met.